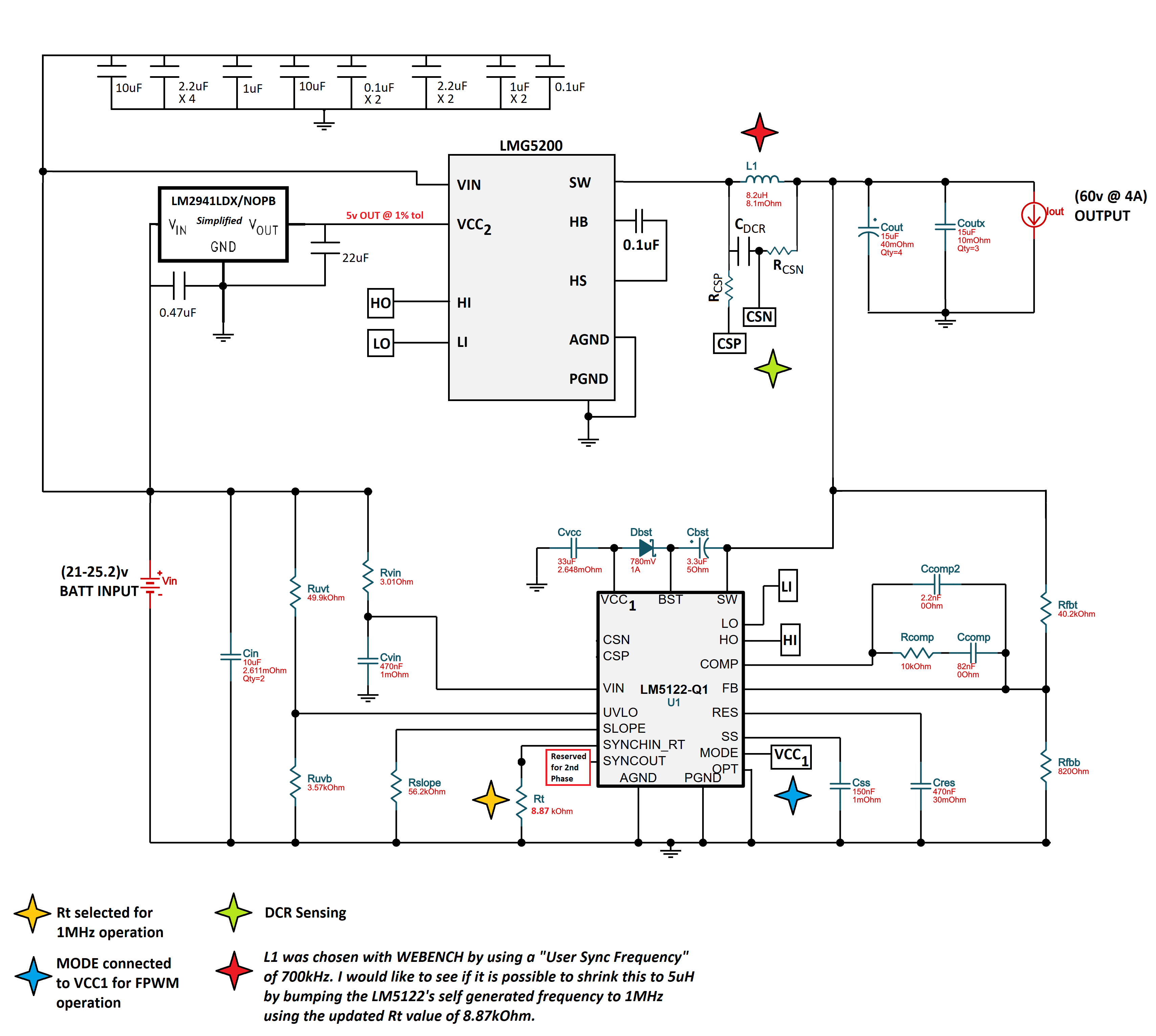

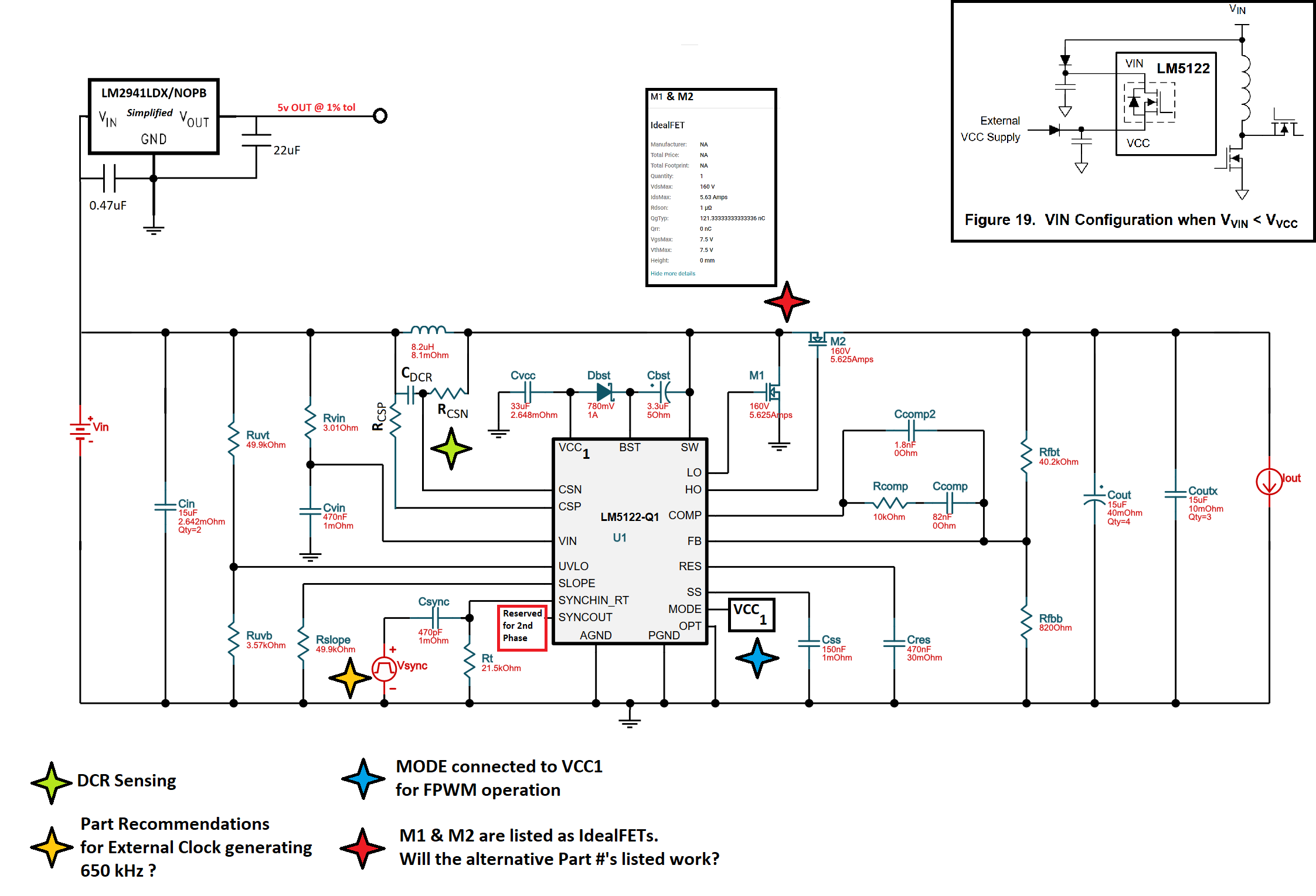

Other Parts Discussed in Thread: LM5121-Q1, LM5122, LM5121, LMG5200, LM5114, LMG5200EVM-02, LMG1210, LM51561, LMC555, PMP11112

Hi,

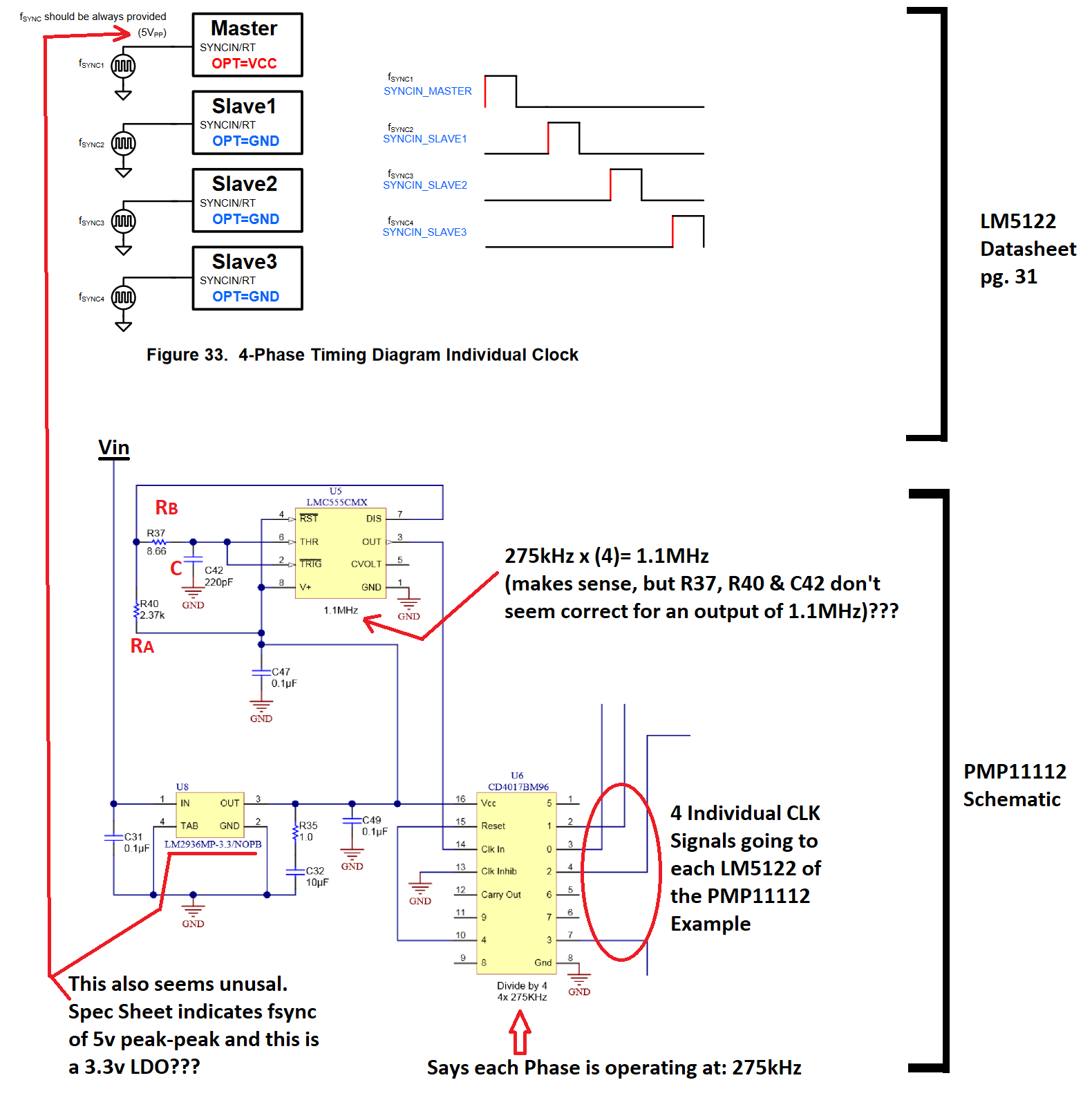

I'm trying to select an appropriate Boost Converter for a new product design. The design input uses (6) 18650 Li-Ion cells in series with the pack specification below:

Battery Spec:

Output pack voltage = (21 - 25.2)vDC

Nominal pack voltage = 22.2vDC

Continuous pack current= 30A

----------------------------------------------

I'm looking for the following output:

Boost Spec:

Output voltage = 65vDC

Output current = 7.5 to 8 Amps

I need this design to be a small as possible and have large heat-sinking options. With that in mind, I've identified (2) Controllers that may work the LM5122-Q1 OR LM5121-Q1. So my questions are:

1) Are the (2) Controllers I've identified the best for this application

2) I've started a Webench design with the LM5122-Q1, but it doesn't look as though you can run a multi-phase design using this tool. I think this application might require such a design.

Please let me know your initial thoughts.

-Thank You,