Other Parts Discussed in Thread: BQSTUDIO,

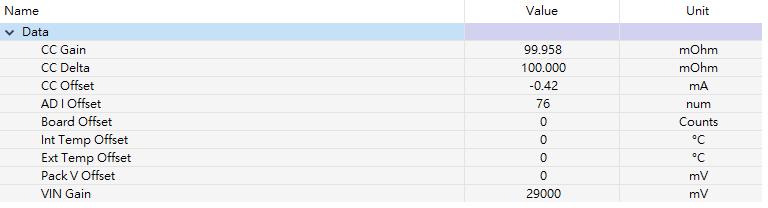

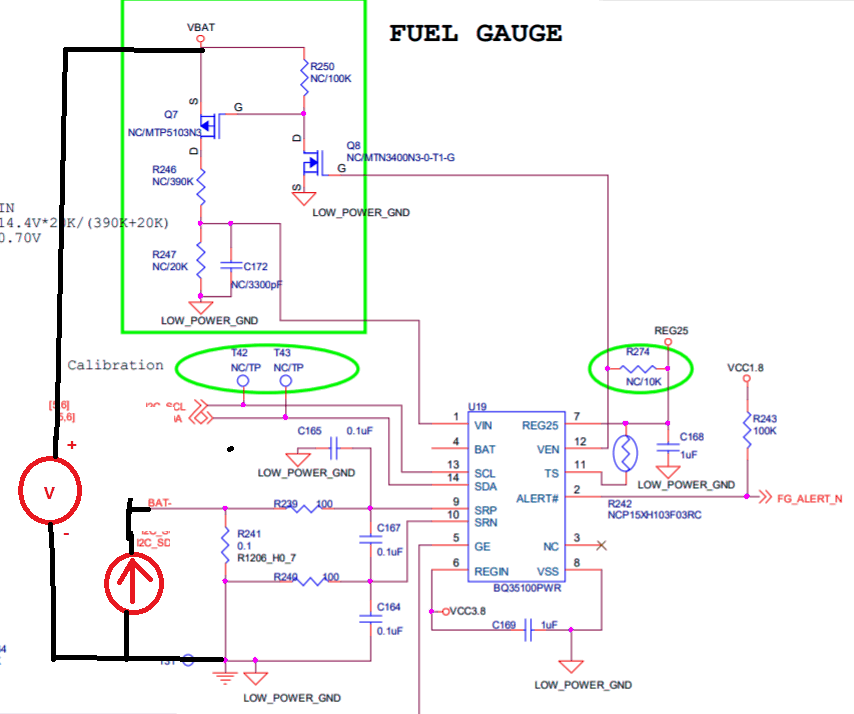

I was trying to do current calibration with 1000mA through bqstudio and making golden image.

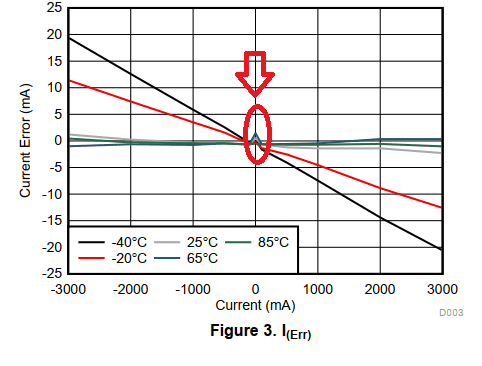

But after calibration process, gauge reported current was not changed and still showed 1020mA as usual.

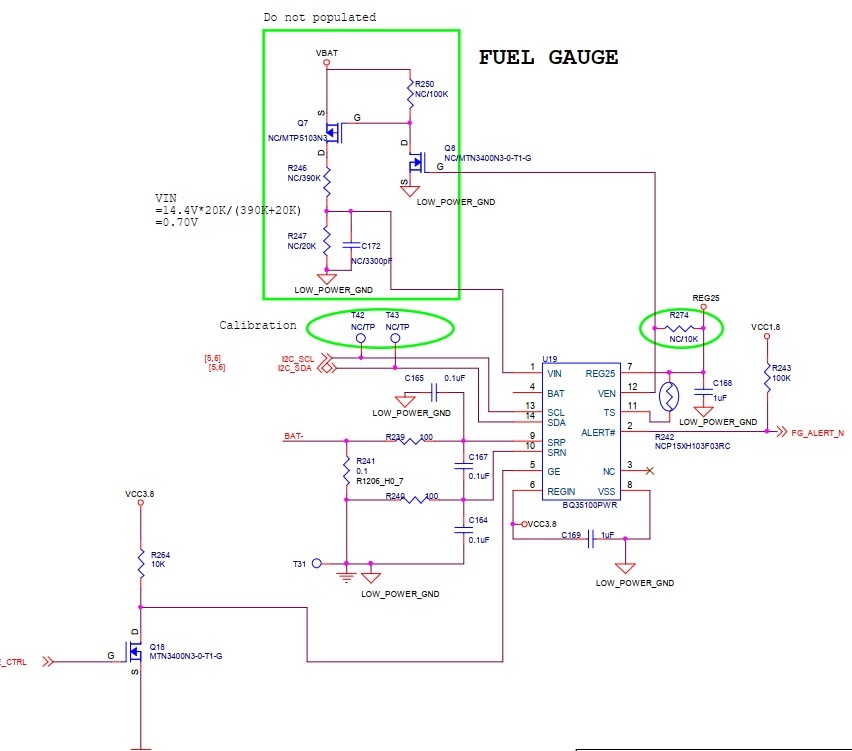

Gauge firmware is default. Schematic is attached and please note that components related to voltage reading are removed.

Please help to look into this. Thanks.

-Jimi