Hello,

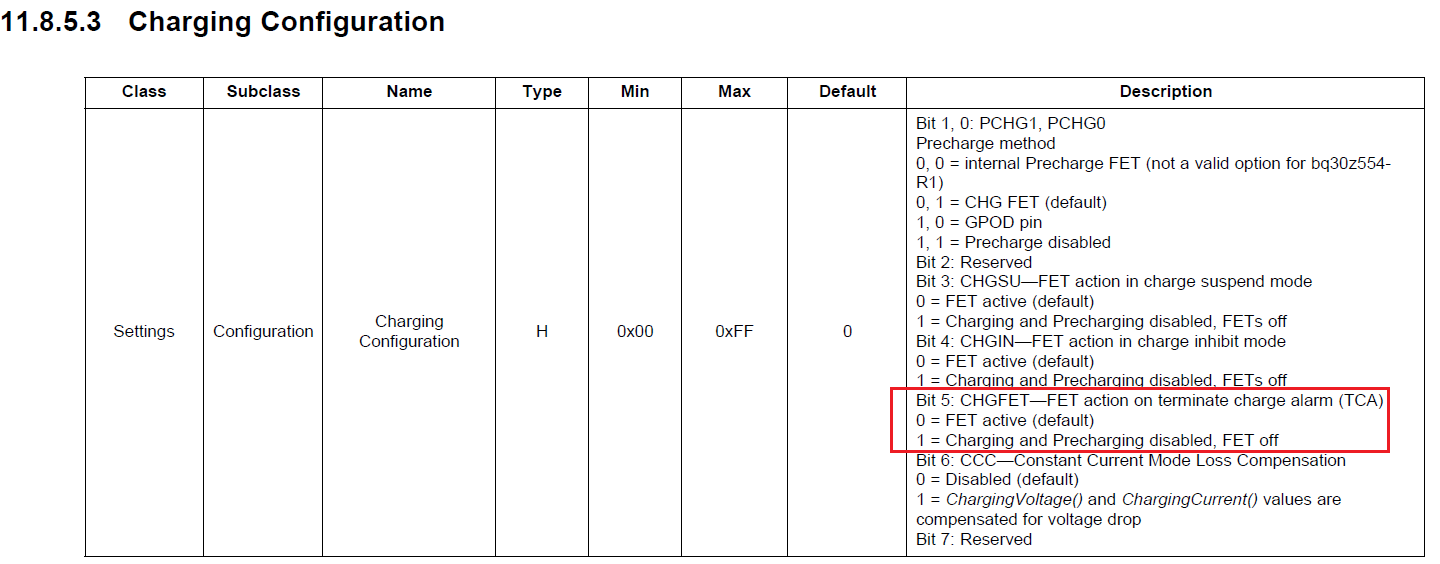

My customer has their equipment placed on the charger and they are using the Terminate Charge Alarm to disable the CHGFET when they get close to their full charge voltage of 8.40V (2S Li-Ion). They ran into a test condition where the TCA bit was enabled (after a valid charge termination), and the system was slowly floating/discharging and the CHGFET was off as expected. However, the charger lost power (due to A/C power loss), and restarted. The charger saw that the battery was less than what it considered 100% charge, now at 8.3V, and attempted to charge the system to 100%. This didn’t occur and the device timed out after 3 hours of trying since the TCA was enabled and CHGFET was turned off.

They would like to know a way that the MCU on their equipment can kick the BQ out of Maintenance Charge with GaugingStatus[TCA] = 1. The equipment is awoken from sleep when the charger resets so they have the opportunity to do something.

Is there a way to set GaugingStatus[TCA] = 0 or do something else to have the same effect? The charger will be powering the equipment during this condition so the BQ sees low discharge current. So far the only way they have been able to recover is to issue a BQ Reset command (0x00 0x12) but they recall there was hesitation in handling issues this way in past.

Let me know if you need anything else and thank you in advance!

John