Part Number: TPS92518HV

Other Parts Discussed in Thread: TPS92518

Hi,

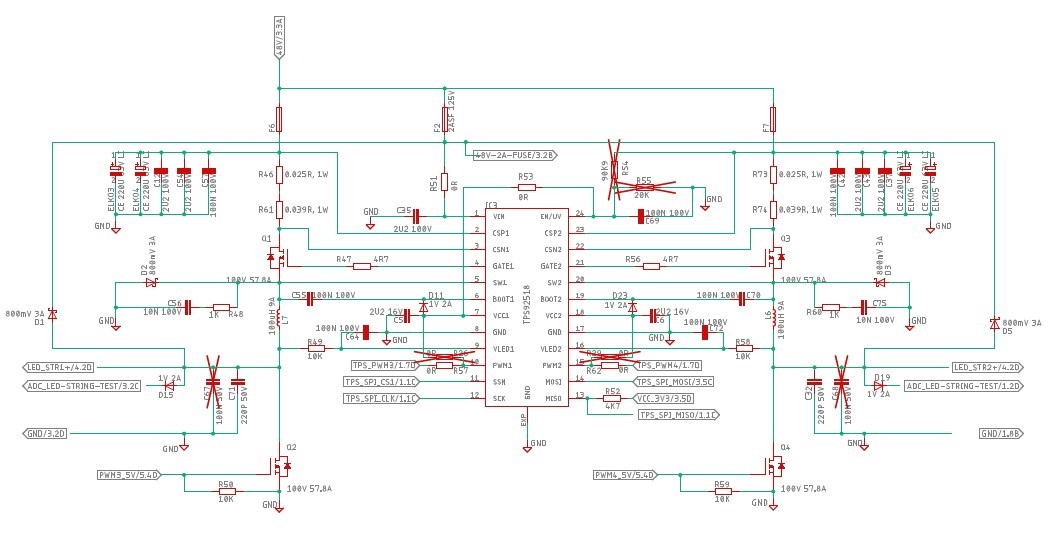

we have done a design with 2 altmost identical TPS92518HV (i.e. 4 channels). The design is closely related to the EVM schematic, see below.

When activating the shunt FET, the TPS dies exothermically and sometimes also the Shunt- or the TPS-FET, even at low LED currents ~200 mA and VCC <= 30V.

To prevent overshoot, we have implemented all suggested measures.

The design should be able to handle at least 5 amps LED current, that's why we used a different inductor type (same L but higher current) and different MOSFETs (NVTFS010N10MCL) as used in the EVM schematic.

Any ideas why that happens?

Regards

Roland