Hi,

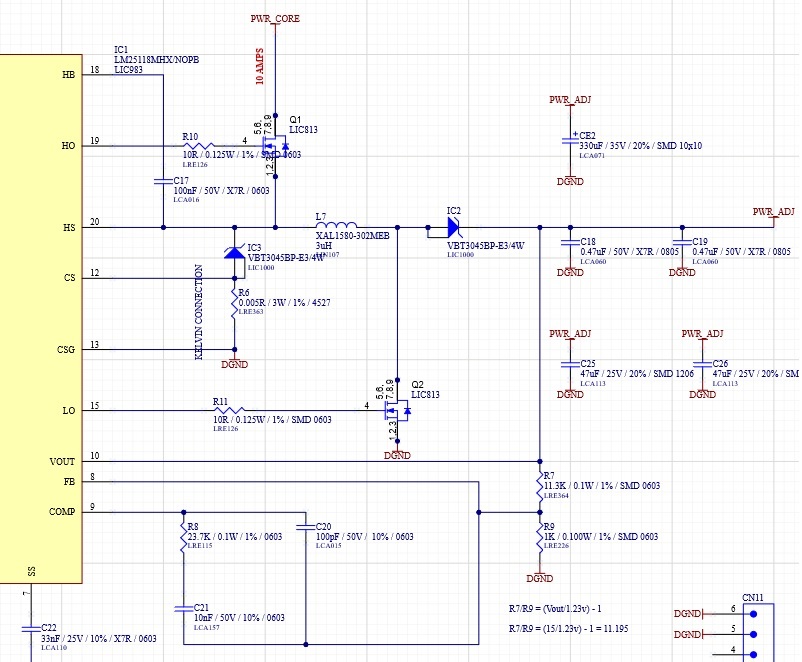

We have LM25118 on a design with V_in = 20VDC, V_out = 15VDC, I_out = 3A: Our RT is 10K.

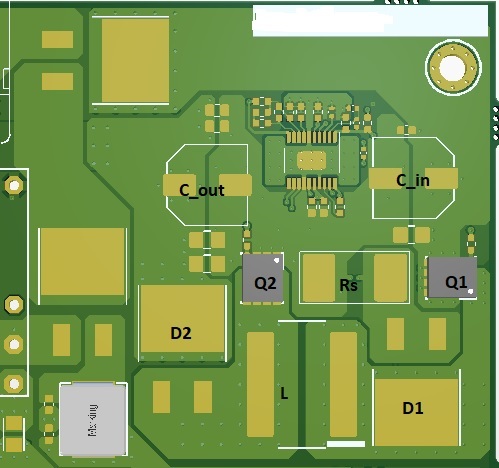

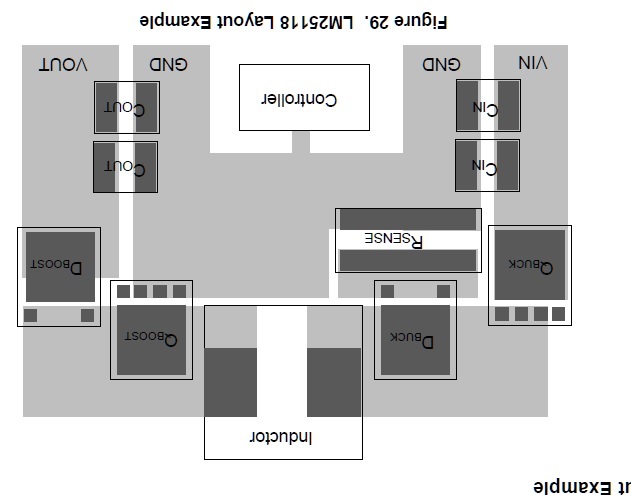

We have a layout based largely on the application note in the datasheet (snvs726f.pdf). The board is 4 layers, 2 Oz copper and is of sound construction.

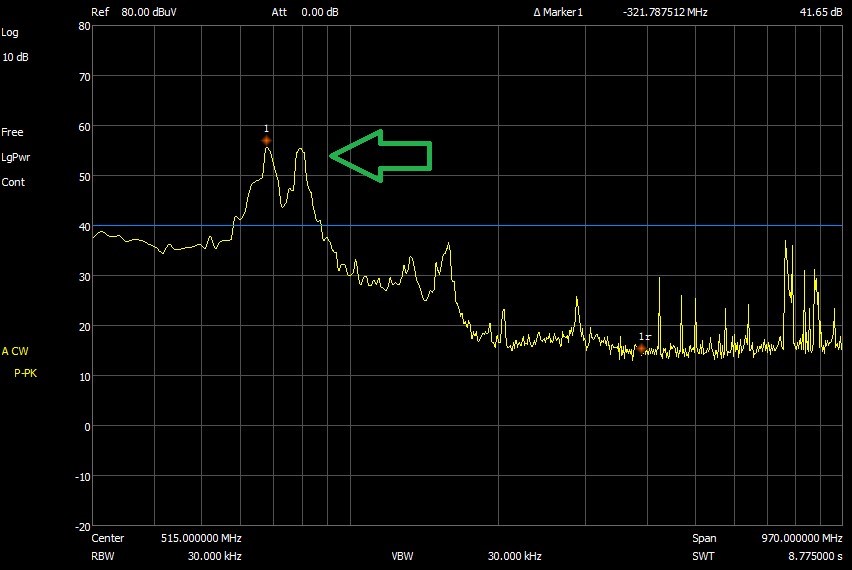

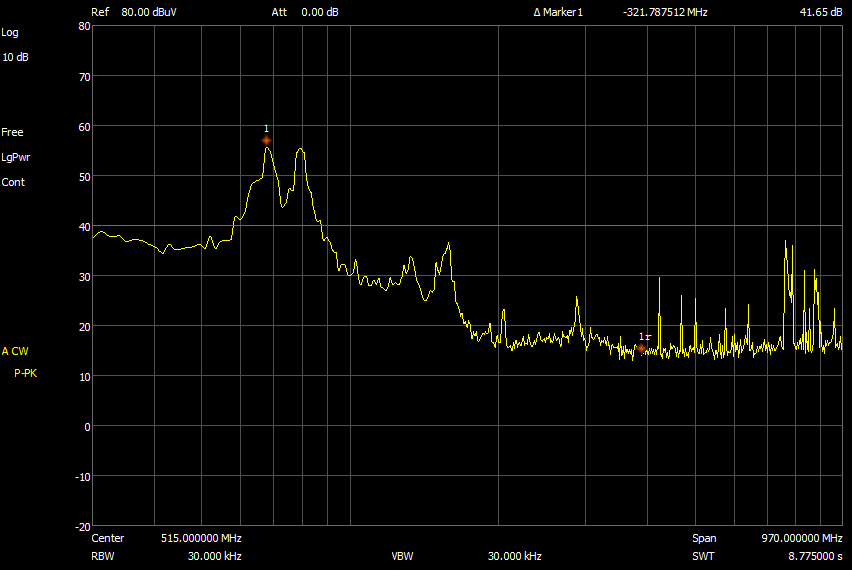

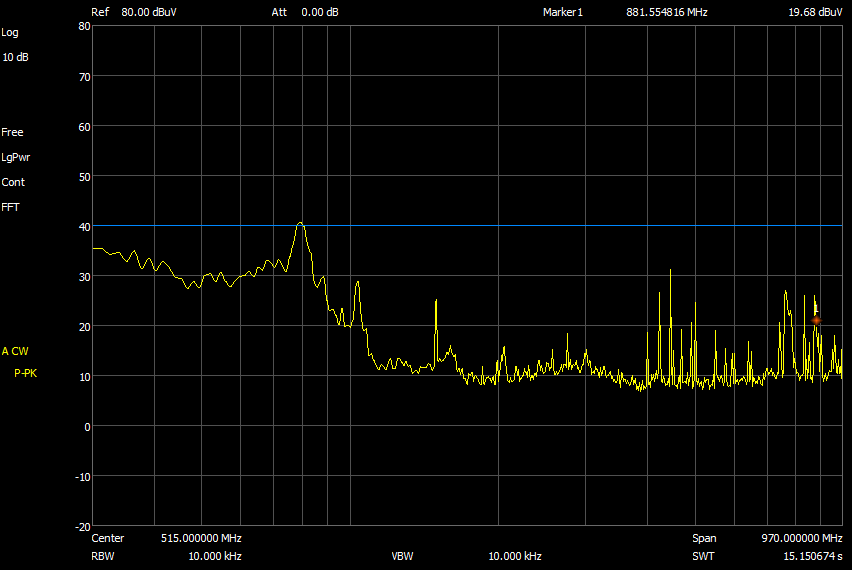

We note that during radiated emissions testing we have some large peaks at about 80 Mhz.

We have tried to build low pass LC filters on the output as well as add ferrites, and none of this reduces the noise by the 10 dB we require. Note that we have placed the filter past D2 (basically at the output of our device).

We have also tried slew rate control on our MOSFETS which have no effect.

I'm seeking TI's expert advice here as where we can look next. Are there other things we can do in-circuit to reduce the noise ending up in the output of our device?. Would the change to a shielded inductor likely help our cause? Anything else anyone can think of?

Thanks in advance.