Other Parts Discussed in Thread: TPS1H000EVM,

I'm using the tps1h000 in hold mode with current limit set to 850mA

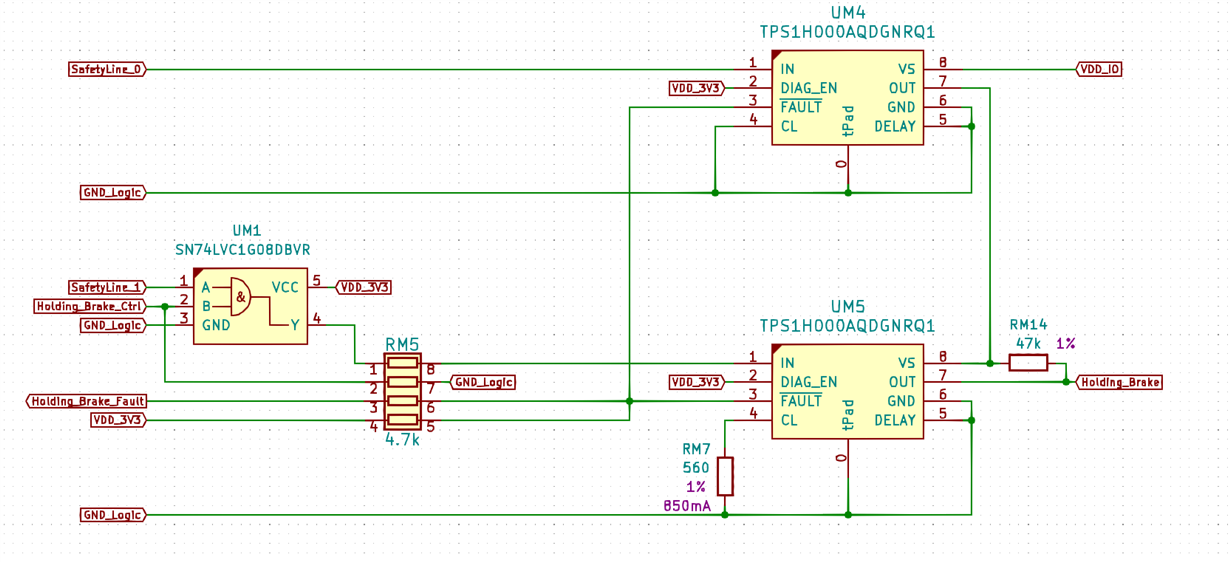

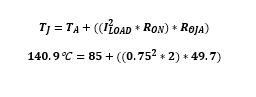

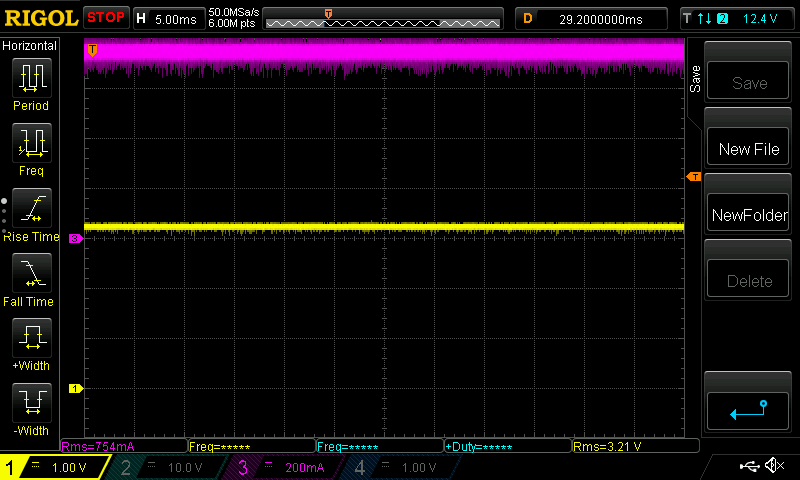

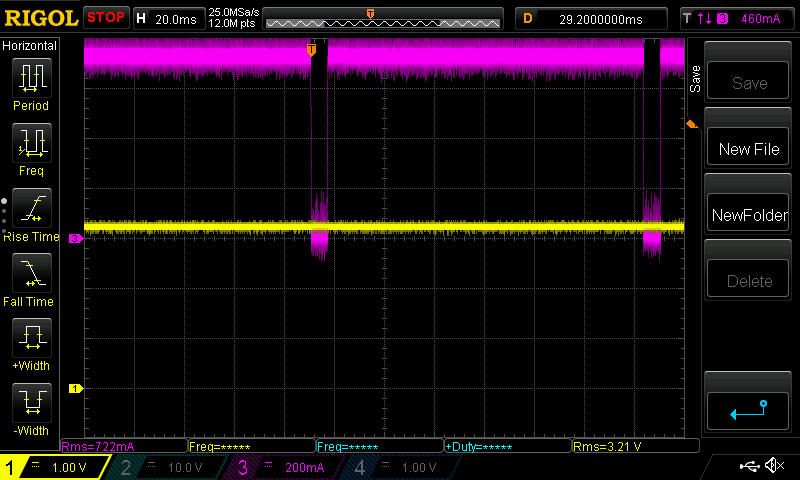

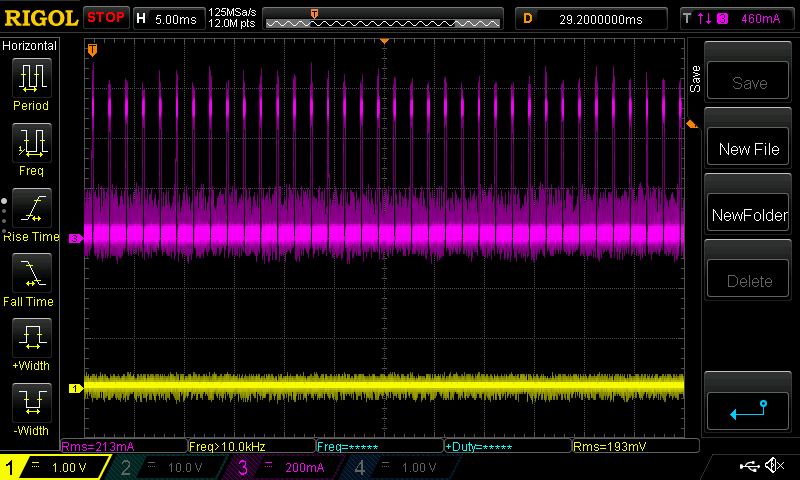

Please ignore the additional fluff in the schematic. For all intents and purposes, I'm describing a situation where both UM4 and UM5 have 3.3V on their inputs. When I load the output (Holding_Brake) to approx 750mA, the chips heat up and in about 30-40 seconds one of them begins cutting out it's output temporarily. This is all just fine and I will address it by switching to tps1h200 and providing more copper. The issue that I'm seeing however is that when the chip begins to cycle it's output off, the fault pin does not pull low, so the MCU doesn't know about the issue.

The datasheet ( on page 15 and 16 ) clearly shows that a thermal shutdown should activate the fault pin, but I can't get it to do so. The timing diagram on page 16 shows the output toggling on/off and I've confirmed that it does, but the fault pin never goes low. If I overload the output, the current gets clamped and the fault pin pulls low. If I have no load, the condition gets detected and the fault pin goes low. So I can confirm the fault pin operation and the MCU reading it properly.

Just to make this clear, in my problem scenario, the load never reaches the limit set by the CL pin and I believe the chip overheats due to it's 1-ish ohm resistance. Is it possible that if the chip overheats while NOT in current limit, the FAULT pin doesn't pull low?

Thanks in advance