Other Parts Discussed in Thread: USB2ANY, DRV10983,

Hello

1. Can I test the TIDA00652 design , with a DC electronic Load? I have been testing my design based on the reference circuit along with DRV10983 + USB2any to set constant load of a bldc motor, I have some issue with few board which I have to test with constant load.

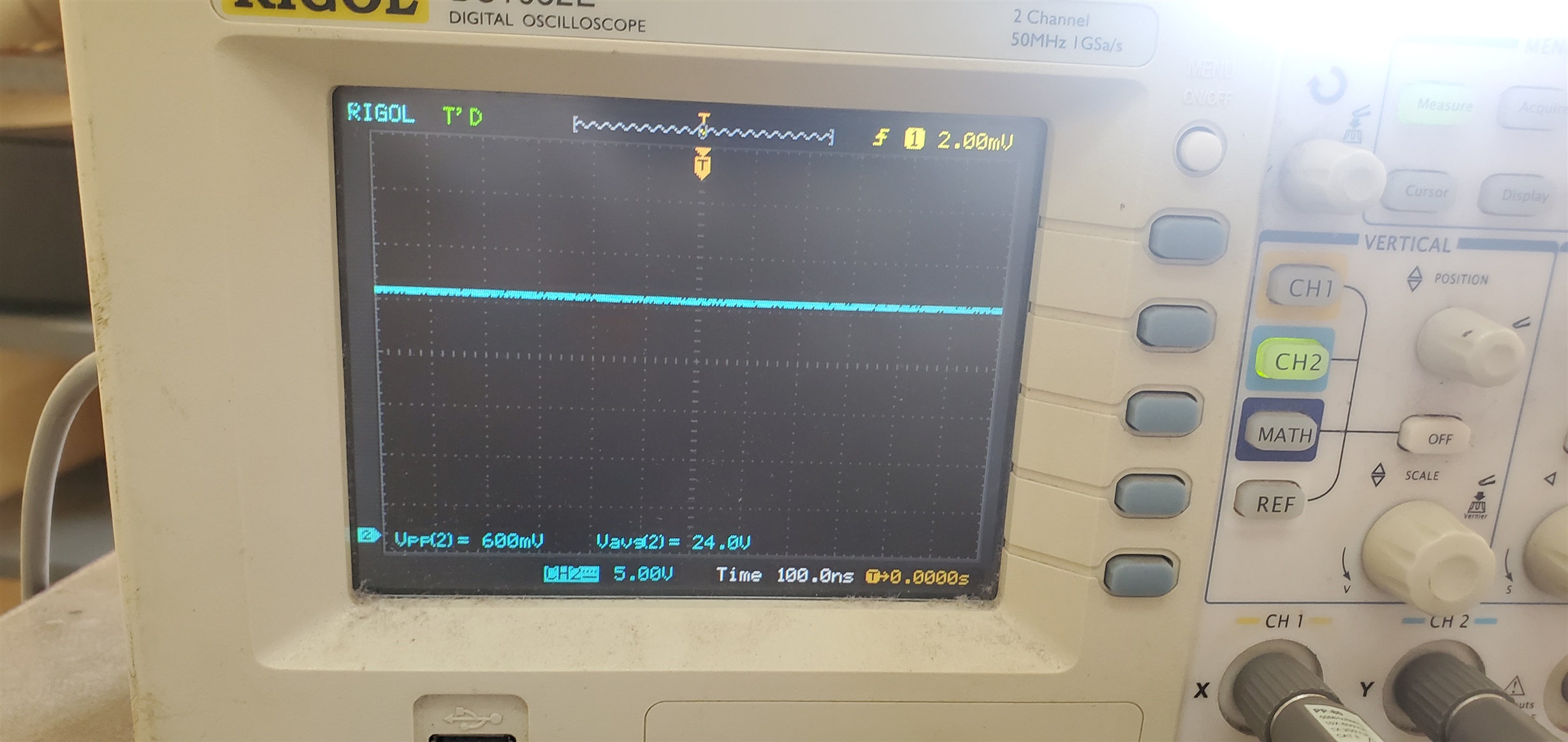

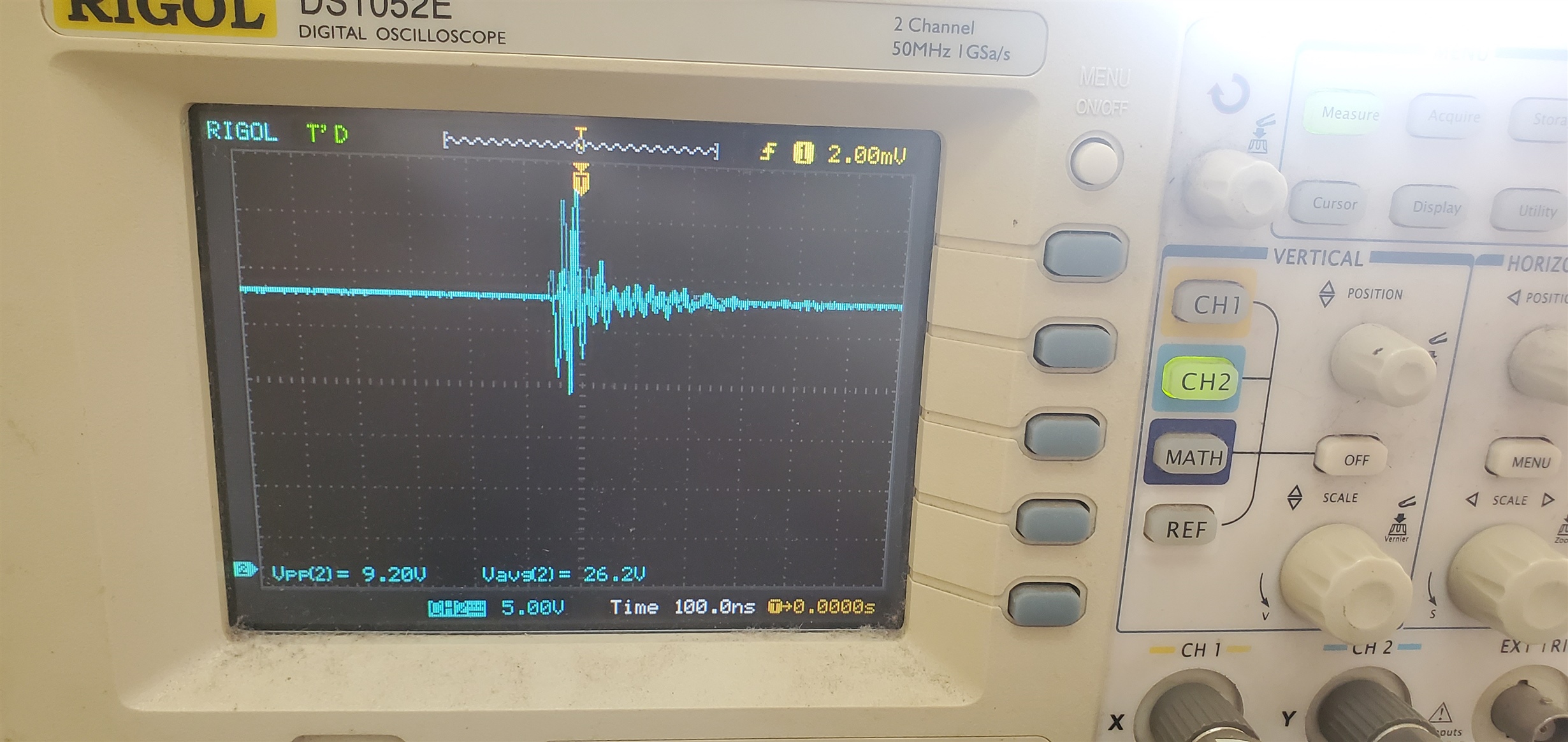

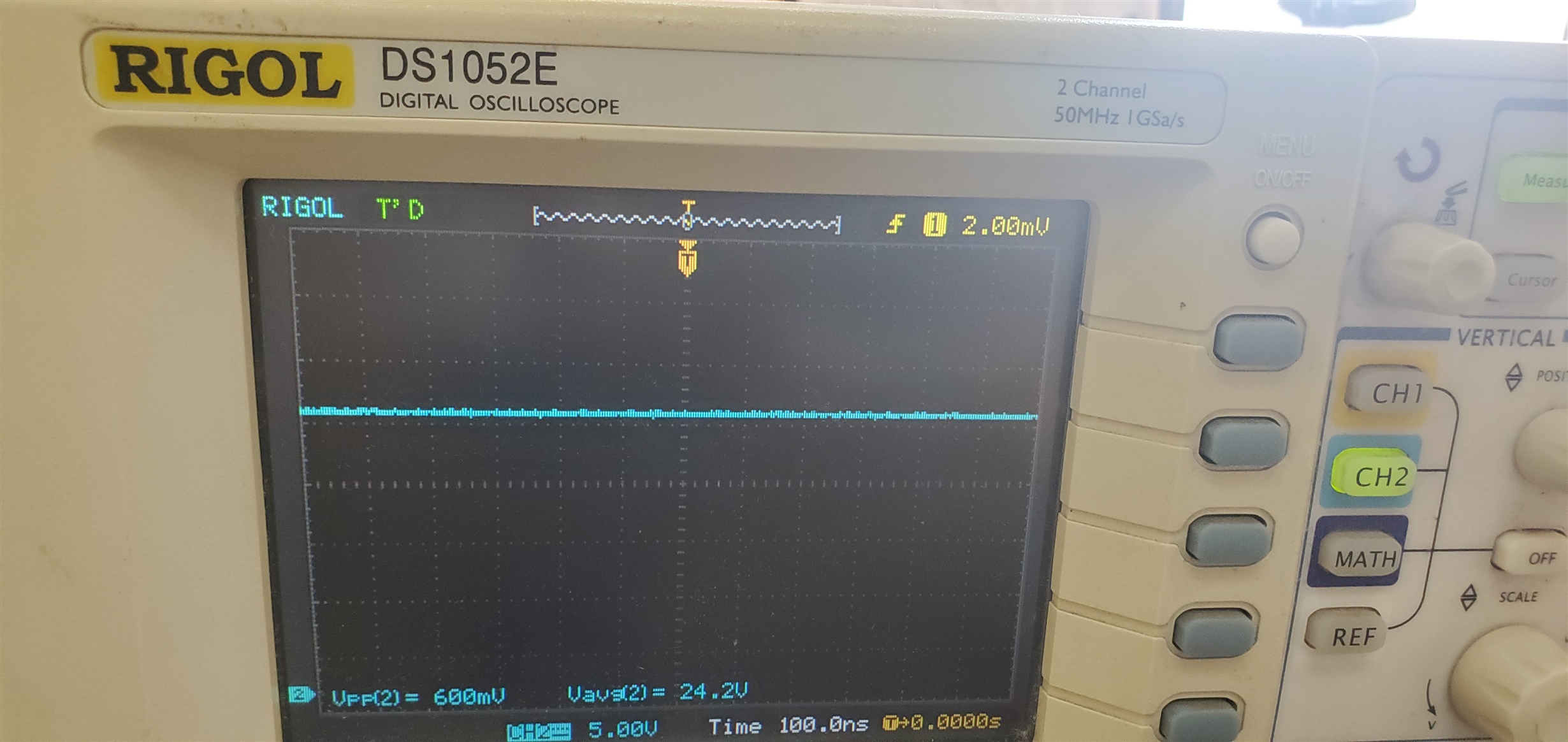

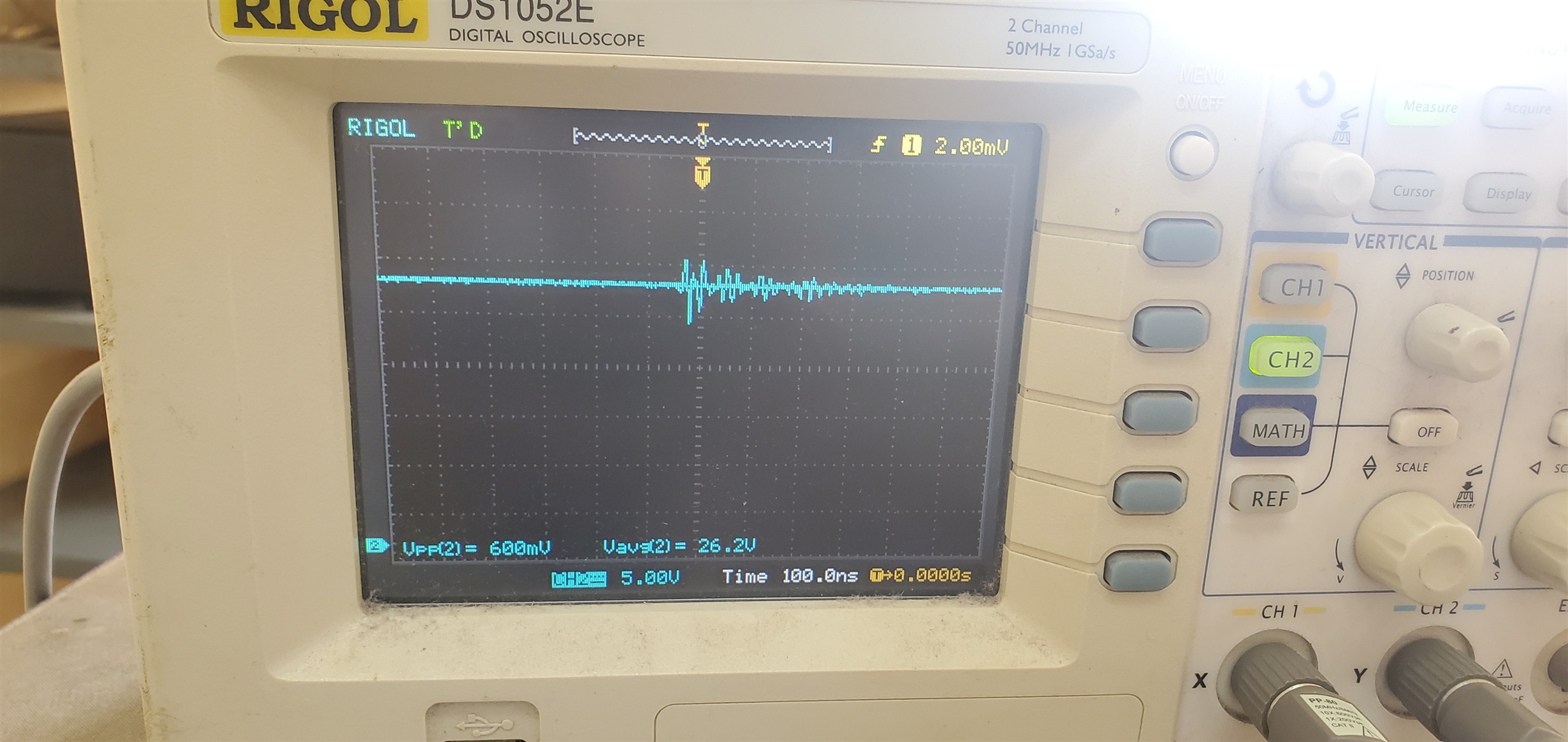

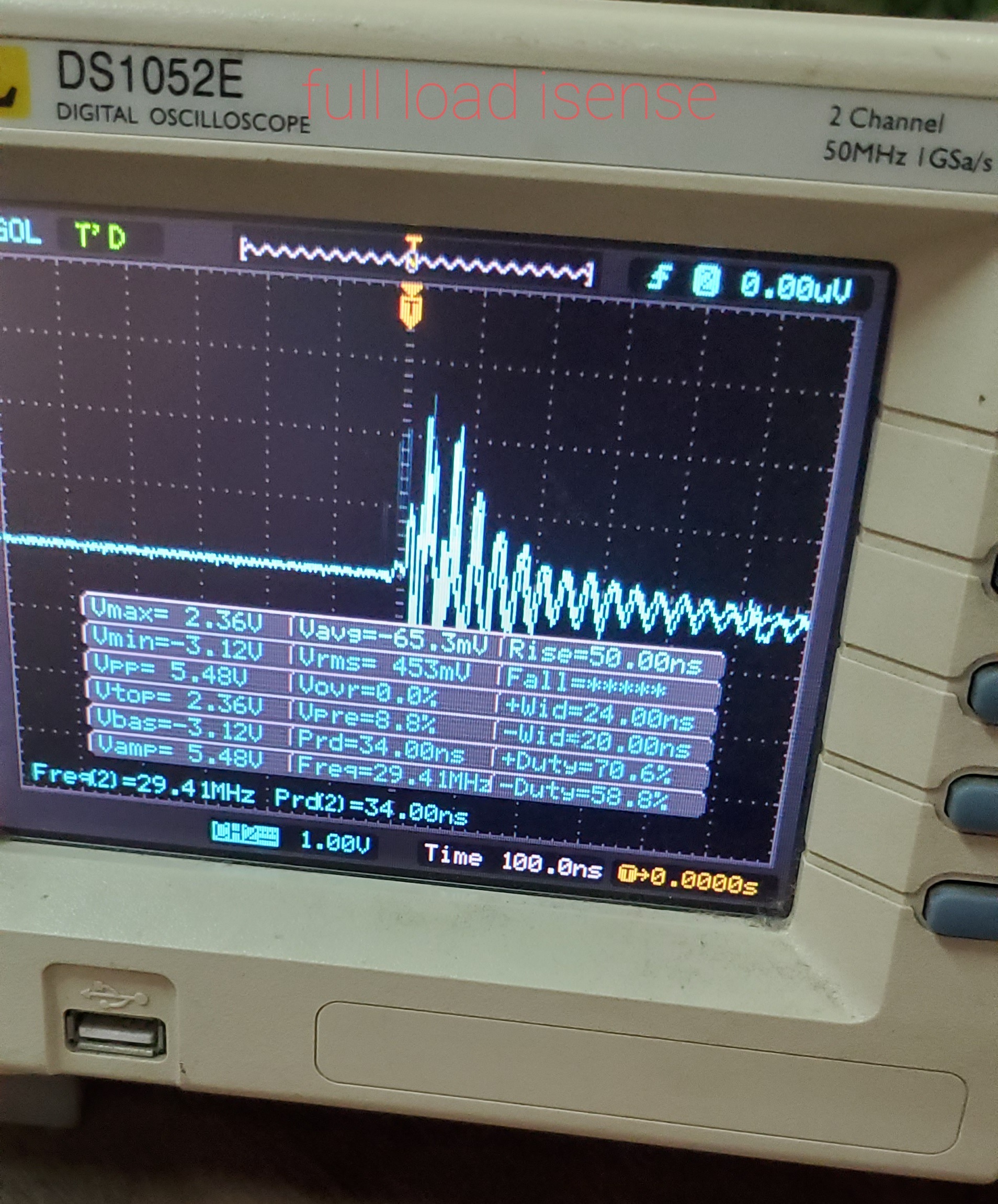

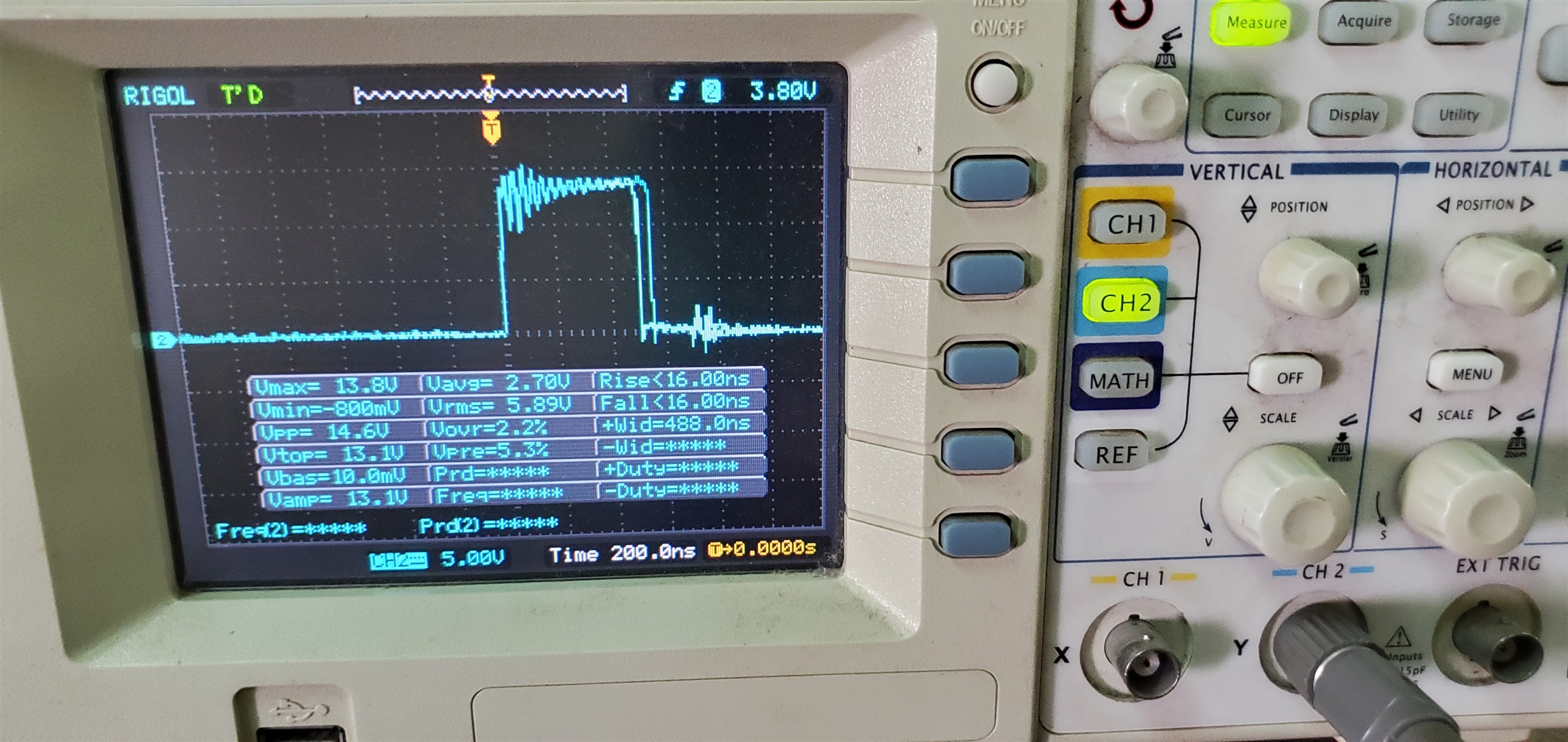

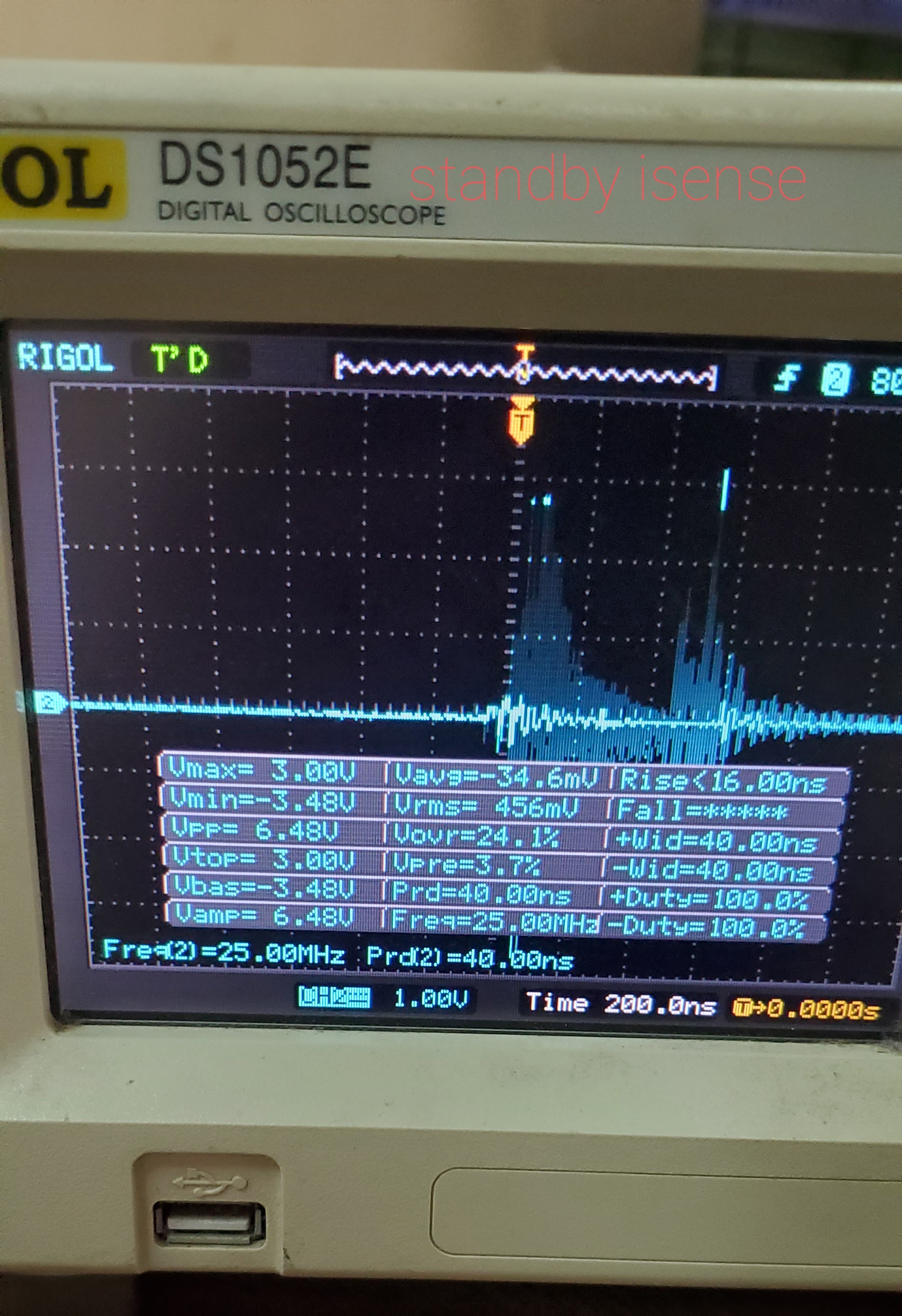

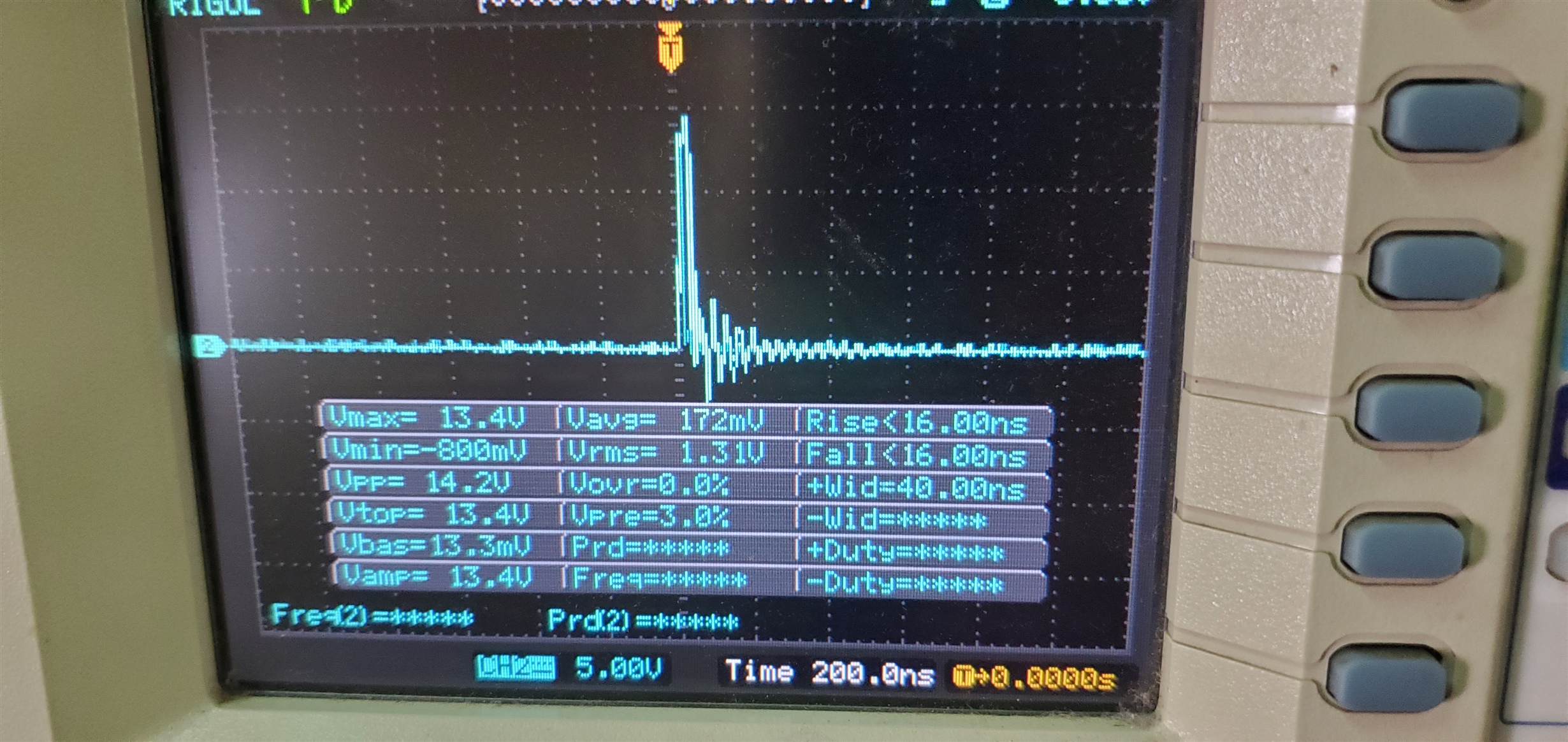

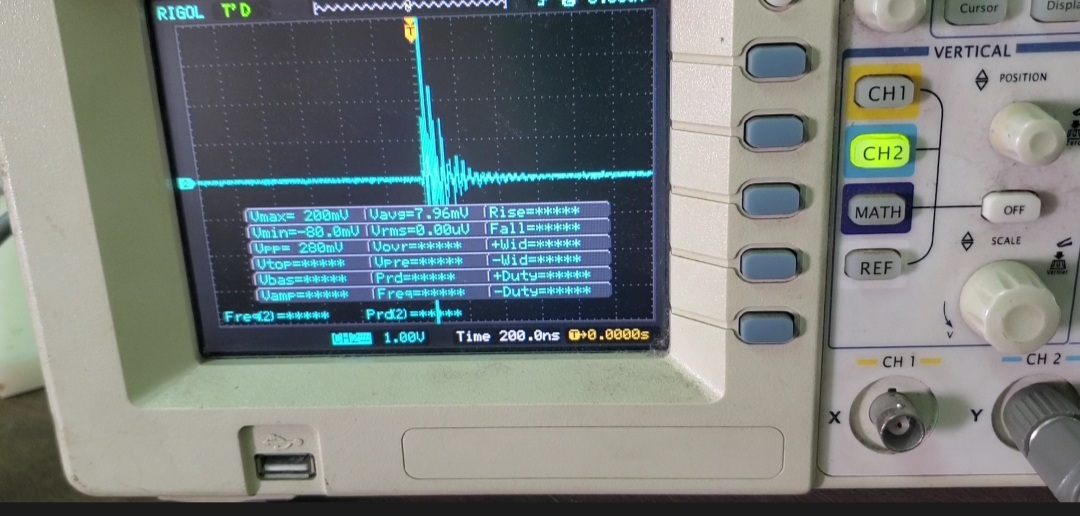

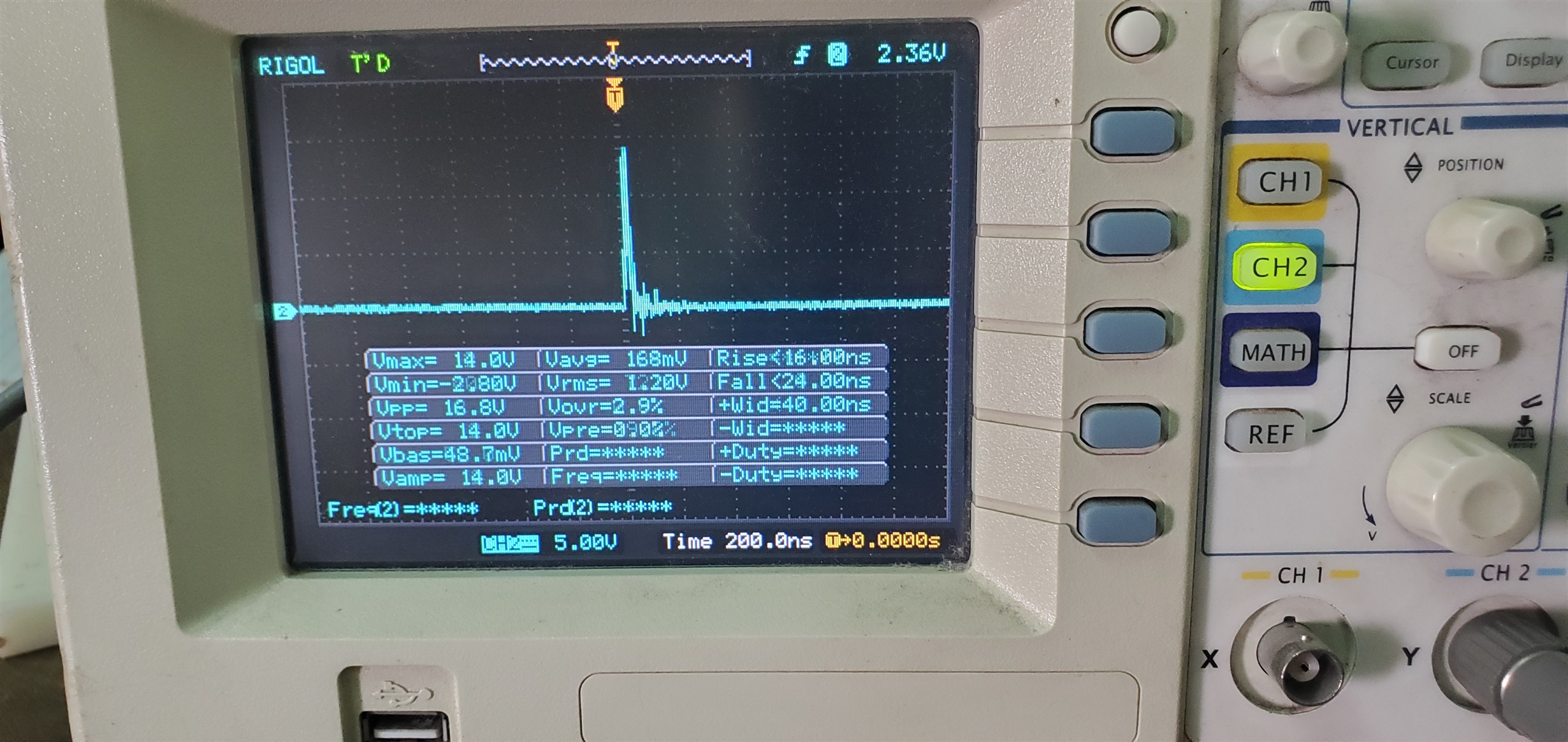

2. TIDA00652 , has been working fine , but I am facing some issues some boards, they can't seam to follow the actual current control, That is when I try to run the motor load of around 12W at 24V ( current draw should be 0.5 to 0.6 amp), the input current draw crosses 0.250Amp, and the power supply goes in protection, all the components on the working boards and the boards that have this issue are same. The output of the power supply stays between 23.9 to 24.6 volts , even the DRV reads similar voltage, but the voltage at TP2 increase from 4.9 at standby mode to anywhere between 15 to 30 volts.

The test rig used is same for all the boards, including the DRV board.