Other Parts Discussed in Thread: BQ27542EVM, BQSTUDIO, BQ25895, GPCCHEM

Hi all,

I have the Bq27542 development board and I designed it myself, similar to the Bq27542evm kit.

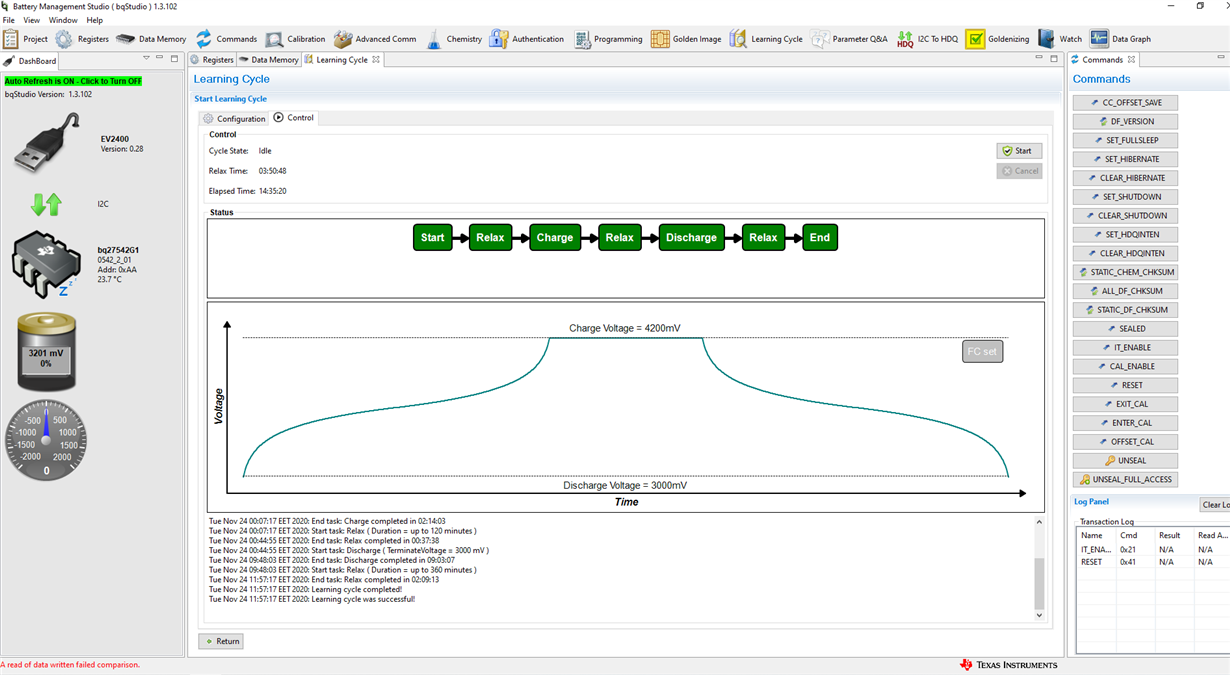

I have a 18650 li-on battery that I don't know about the chem ID and I use a learning cycle to learn my chem ID with BQstudio.

I'm following these steps for the learning cycle:

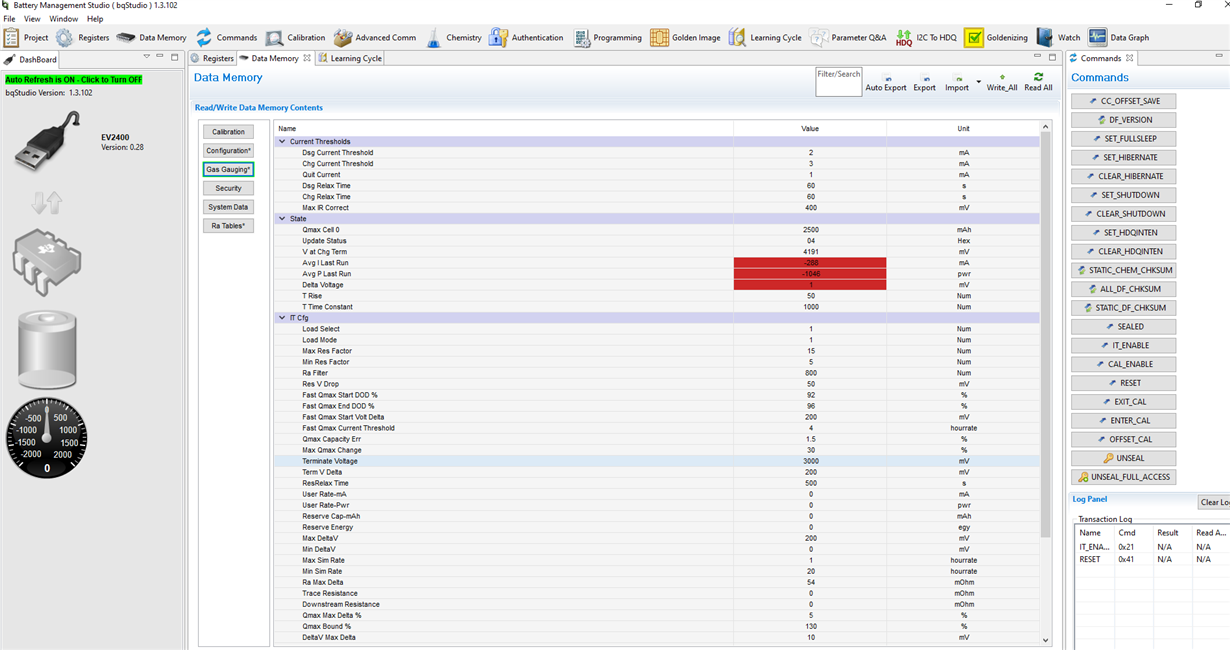

- I made Data memory adjustments according to the characteristics of the battery.

- I pressed the auto export button from data memory at 15 min intervals and started logging in the register part.

I am adding them.

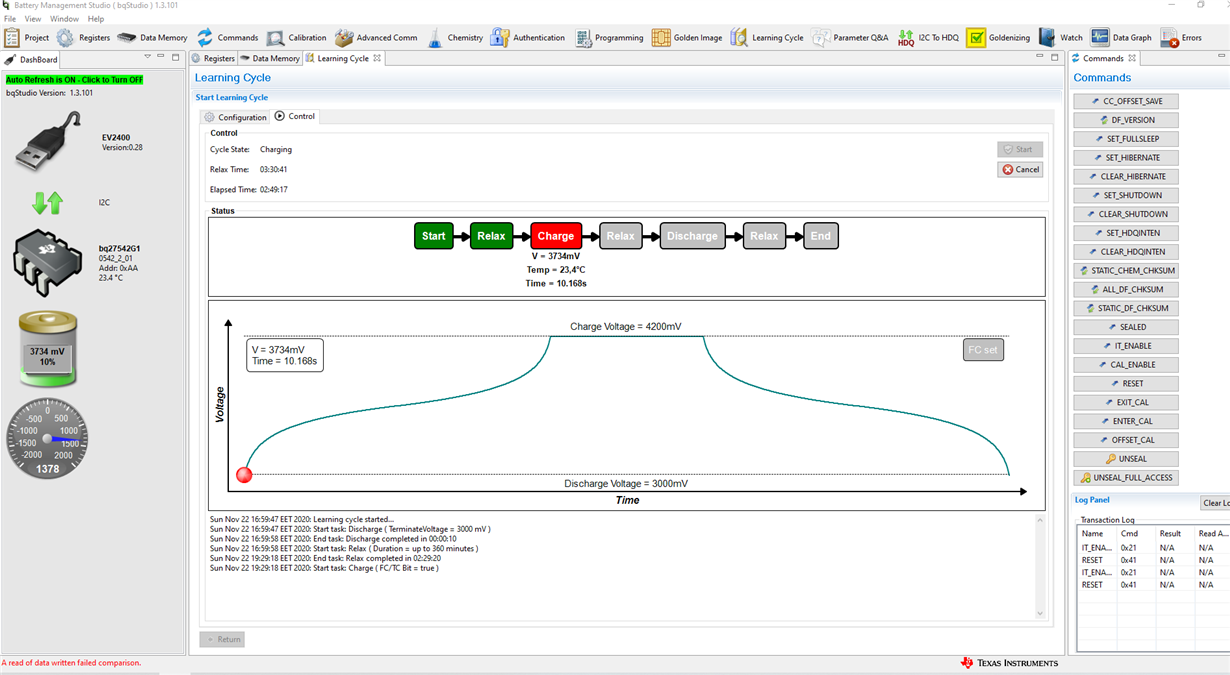

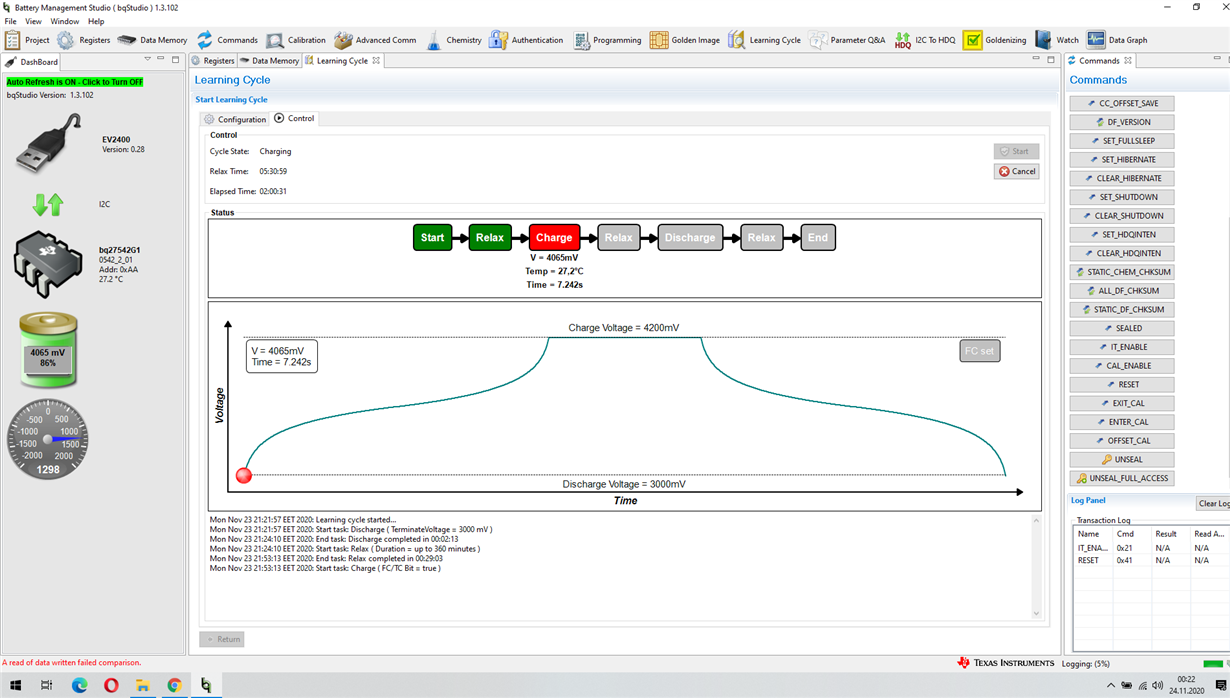

After starting the learning cycle, while watching continues, I start to see 'A read of data written failed comparison' at the bottom left.

Q1) Why is this happening?

The first time I saw a warning, bottom left.I did not physically interfere with the system.

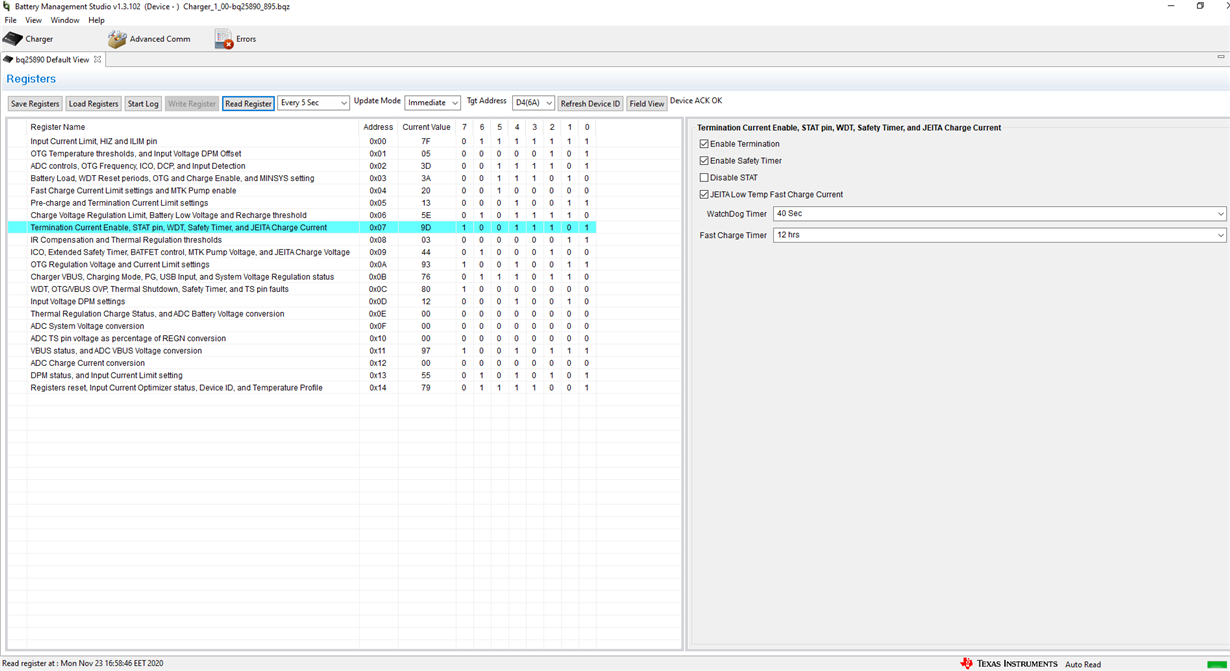

Also, while the charge process continues, the FC bit is not set and my charge process stops after a short while. I am doing the charge process with BQ25895. (this may be stopping the charging process.I'm not sure)

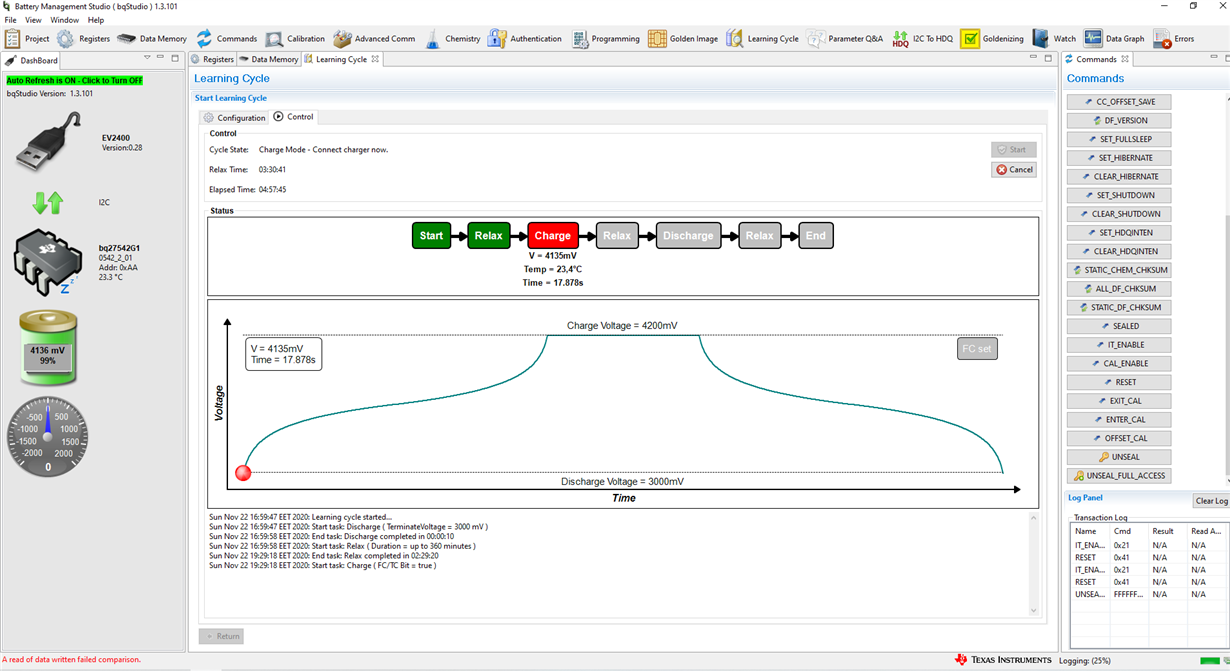

Since the charging process is stopped, it stays in charge mode and I get a warning that I need to connect the charger. I unplug the charger and plug it in again and the voltage comes to 4193mV, again the chage process is interrupted.This cycle continues continuously.

Q2) I cannot go to the next step without setting the FC bit. how can I do that and the next question here might be related to my first question?

The moment the charge process goes up to 4193mV and the charging process is disabled

4812.test.logBatteryManagementStudio.rar

PX-18650_2500mAh_datasheet-REV001.pdf

I am using 1200-1300 mA while charging.

I've been dealing with this for a week, and sometimes I follow it before I sleep because the tests take a long time. How can I solve it? Can you help me? I need to learn chemID and start using it as I want.

Regards,

Mehmet