Other Parts Discussed in Thread: TPS92518, , TXB0108

Hi,

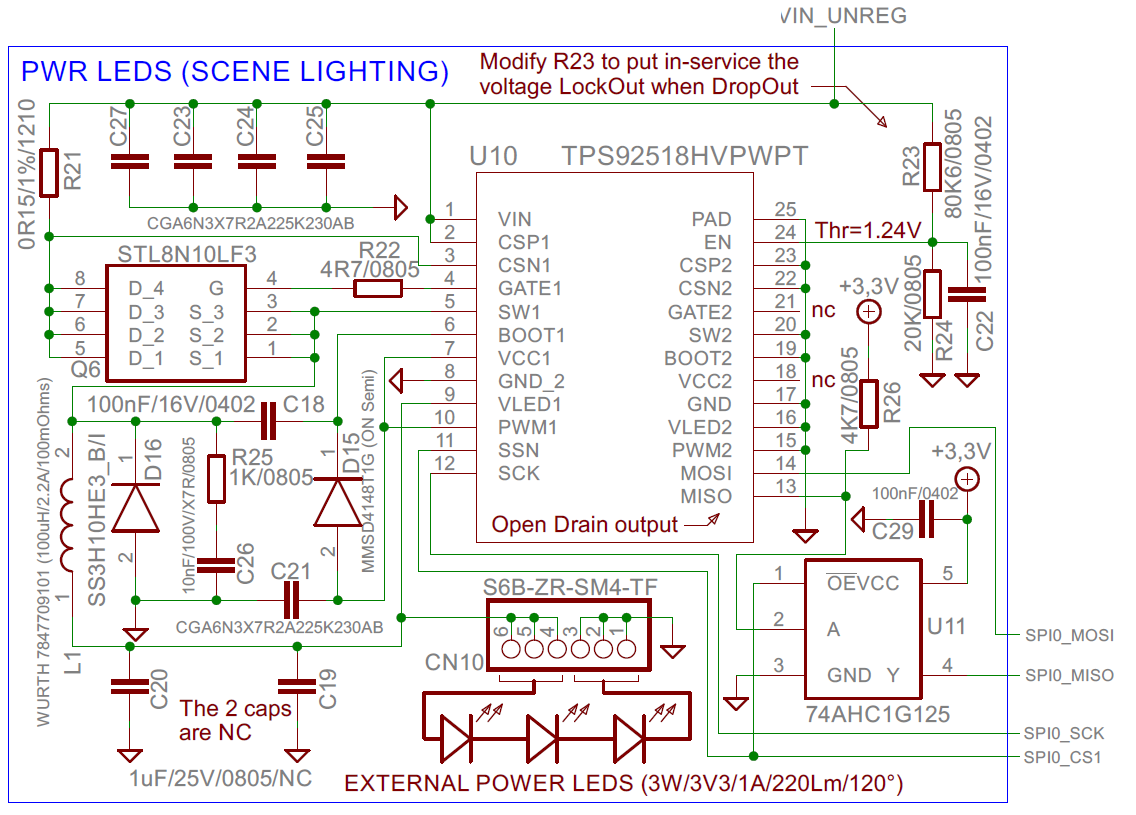

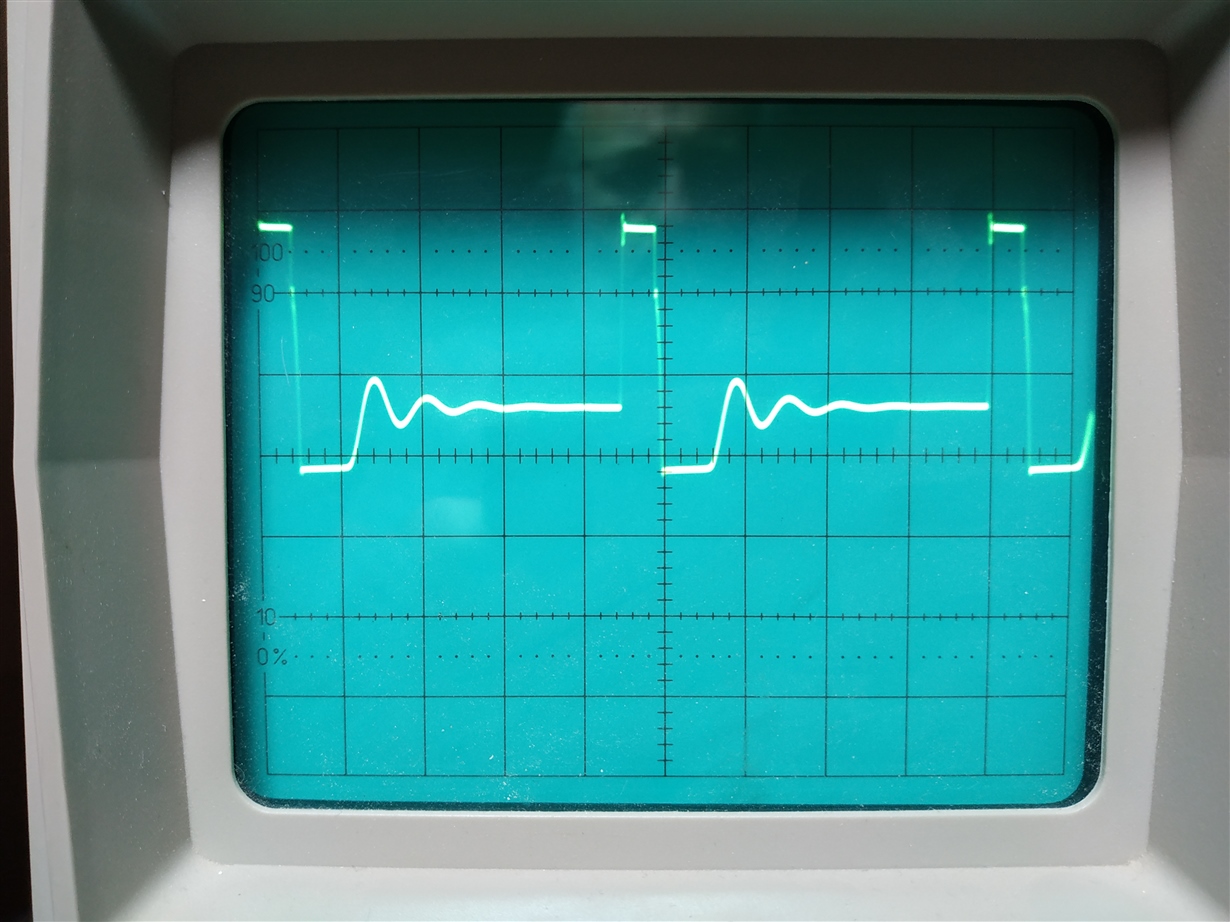

See the schematics attached.

SPI communications works well, no problem on this side and my first tests changing the LEDs brightness were also OK

But I burnt the assembly (now out of order...) with these parameters:

VIN_UNREG = 20V

VLED = 10V

3 serial LEDs, 3W each

Ipeak LED = 933mA (register LED1_PKTH_DAC = 140)

LED1_TOFF_DAC unchanged default value (128)

1rst questions are for HW : why the TPS has burnt with theses parameters (after 10mn) . Except the external LEDS itself, nothing was hot (< 60°C) when this occured.

And what are the components out of order ? (TPS, MOSFET Q6 , diode D16 ...). I dont get any tools to check.

Concerning the LED1_TOFF_DAC: I did not modify its value according my parameters as specified in dataSheet page 15.

And how can I modify this register when my VIN_UNREG ranges from 10V...60V (it is a specification condition) and VLED ranges from 7V (min brightness) to 10V (max brightness).

I'm aware that when VIN_UNREG = 10V, I cannot get VLED = 10V. But I wish the maximum brightness possible with a 10V VIN_UNREG

Thanks by advance for your help