Other Parts Discussed in Thread: GPCCHEM, BQ34Z100, BQ34110, BQ34Z100EVM

Hi TI expert,

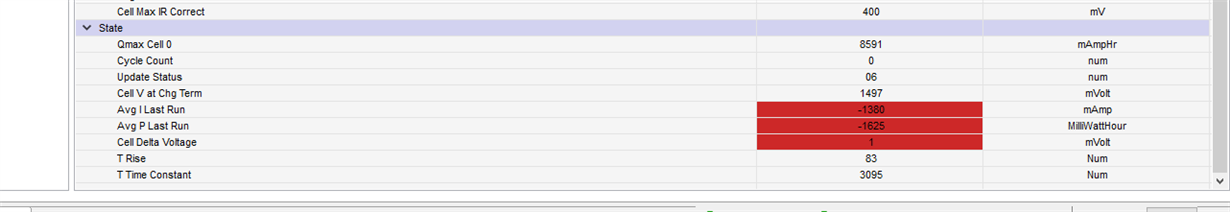

I am using BQ34Z100-G1 to monitor a 12S NiCD battery. The capacity of battery is about 7AH. Energy 168WH. Chemistry ID 6103. And I run a learning cycle (charged to full--> wait until RUP_DIS goes 0, OCVTAKEN turns high --> discharged to empty --> wait until VOK goes low and OCVTAKEN high) yesterday. However, I meet a few issues here, please help me out.

1. after a discharging cycle, the learned status was not updated to 5 when the OCVTAKEN is high and VOK reset. I saw in the "4863. How to Completed a Successful Learning Cycle", it states that sequence of learning for the NiCD battery is: charge to full -- > discharge --> charge to full --> discharge, which is different from LI-ON battery. Is the learning status supposed to be updated in the relax time of discharging?

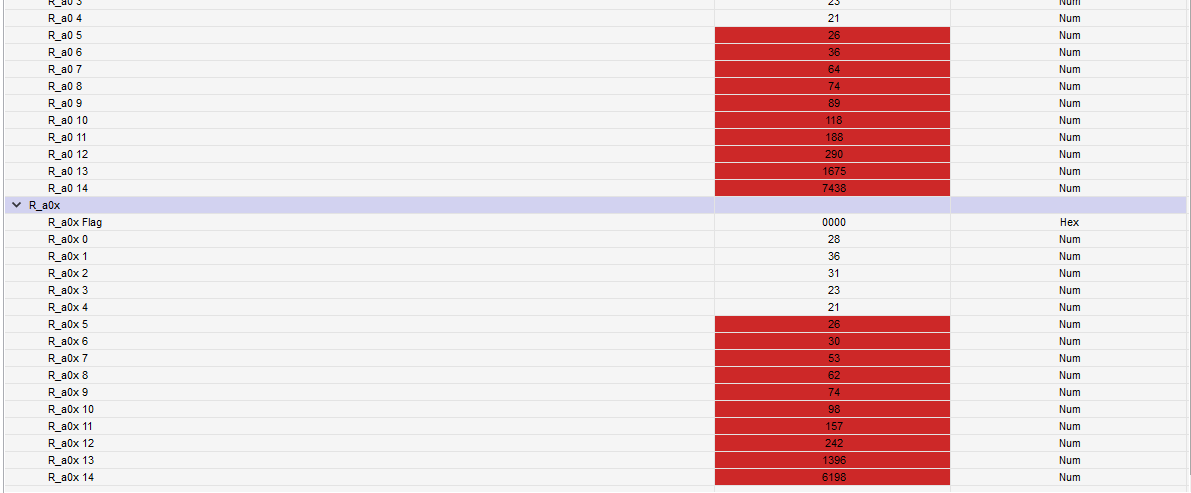

2. The True RC goes negative when it is closed to the end of discharging cycle. And then in relax, it jumps to -3427 and the True FCC jumps lower as well. What could be the reasons for these behavior? (Main problem)

3. Does the charging or discharging current affect the result for NICD battery? It suggests to use C/5 to C/2 current to charge the battery, what if I use C/7? The default charger I have can only charge up to C/7. Another charger has issue when charging the battery, the current drops to 0 once a while. I am not sure why.

4. I saw in some posts which say the Design Energy is the for each individual cell, so I divide 168WH/20 = 8400 mWh for the design energy and make the energy scale to 1. Is it right? The design energy here is cell based or for the whole battery?

5. In the original post, Batt stated that "The log shows unusually disjointed values from the test. The jumps are 20mV each." at the end of post. I got the same voltages in the log, jump 20mV each, is there anything wrong with this behavior?

I have attached the configuration file and logging file. Please help me have a look.

Thanks