Dear sir/madam,

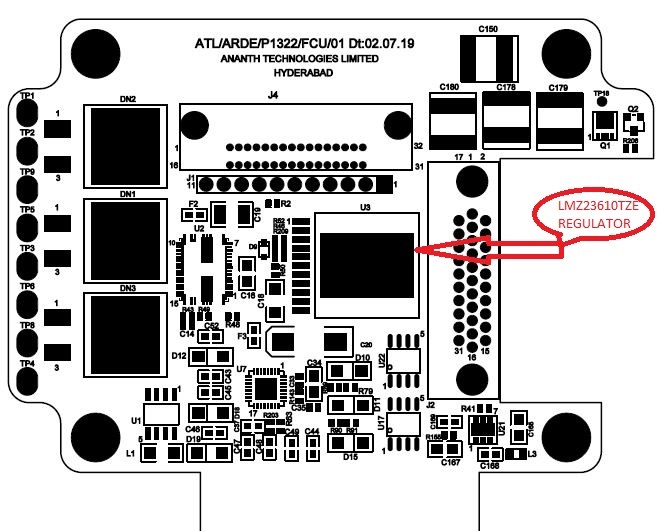

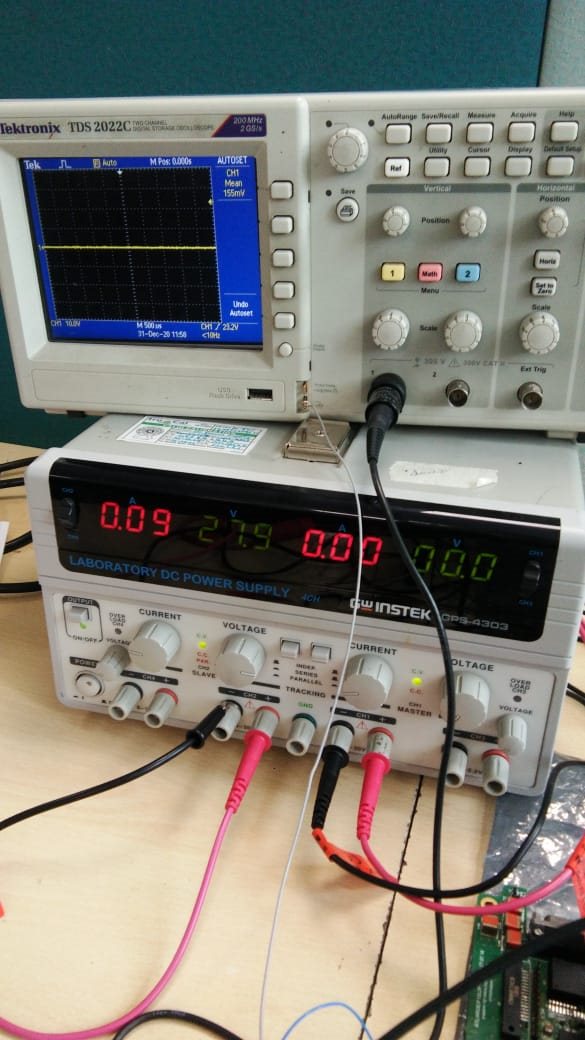

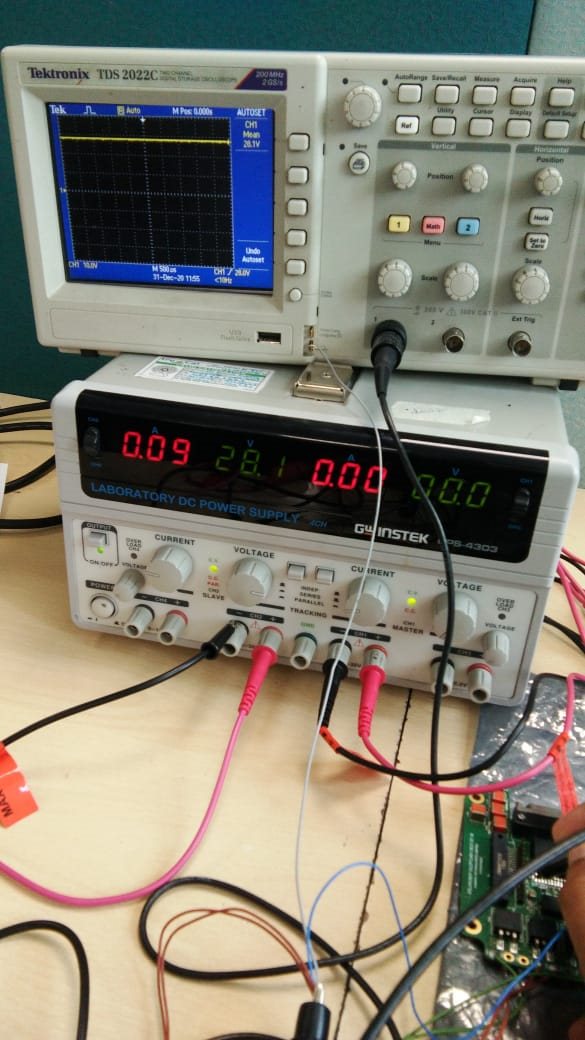

i found an issue for lmz23610tze DC-DCregulator while replacing on the boards.There is no short found on board when placed for 1st time on PCB but when replaced for second time the component is getting internally shorted like feedback pin no7 and ground pin5 getting shorted with 14.4ohms resistance on one board.In another board the component is getting internally shorted like supply pin 1 and ground pin 5 shorted with 1ohm resistance. this short/resistance is observed by lifting the above mentioned pin numbers.AS even i measured on PCB between those pin number and does not found any short on board.