Other Parts Discussed in Thread: , TPS2116, TPS2121, TPS2113A, TPS2115A

Hello team,

we have a hand-held computerized spirometer that works with two AAA batteries or with USB.

We are using two schottky diodes in typical ORing configuration to provide power supply mux function (USB or batteries) and reverse polarity protection of batteries. Power supply from USB takes precende over batteries when device is connected to USB to save battery. Voltage from USB is 3.5V (LDO before ORing diode) and voltage from batteries is between 2V and 3V. The main disadvantage is the power losses in schottky when running from batteries.

We are considering replacing the schottky diode for the LM66100 because of its low price and of course its reduced power losses when running from battery.

The functionality remains the same:

- revere polarity protection from batteries only.

- USB power supply takes precedence over batteries.

- the intended use of spirometer is running with batteries assembled, but it's possible that somebody could use it from USB only without batteries.

We are discussing three topologies:

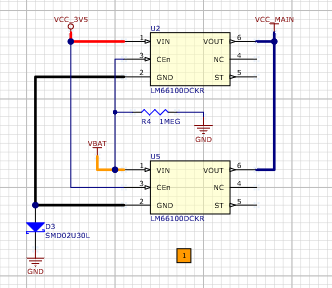

1) two LM66100 in ORing configuration with RPP by means of series resistor in GND pin to limit current

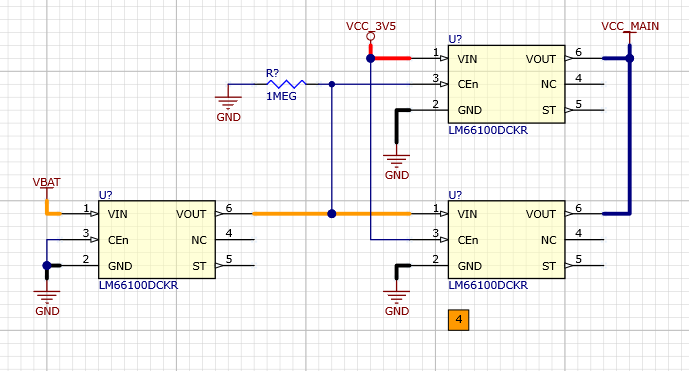

2) two LM66100 in series: first in RPP configuration and second in ORing configuration with a schottky diode in USB pwer supply path.

3) one LM66100 in ORing configuration with a Schottky diode in USB power path with RPP by means of series resistor in GND pin to limit during negative event

There are still some questions regarding these circuits.

- Is there any difference between RPP by means of serie resistor or RPP configuration (fig 12 of DS)? Is one circuit better than the other? I mean, in both cases load is protected from battery reverse polarity, so is it really necessary to add a dedicated LM66100 to RPP as in topology 2?

- In ORing configuration when batteries are assembled in reverse polarity the only possible path for current flow from battery is through GND pin to /CE pin, no currents flows through the load, right? Could we use a 10k series resistor to reduce current further during negative voltage event?

- What happens with /CE pin in ORing configuration if one of the power supply source is not present? In that case one of the /CE pins would be floating. I test with LM66100EVM in Vin1 and Vin2 and it always works but not sure if it's better to add a pull-down resistor (we don't want to add components if it's not really necesary due to space and cost constraints).

- In ORing configuration could we share one series resistor for both LM66100 GND pins instead of two series resitors, one for each LM66100, as in LM66100EVM?

Any advice on circuits proposed? What circuit do you think works better?

Best regards,

Ignasi