Hi All,

I would like to ask a question on TVP54310.

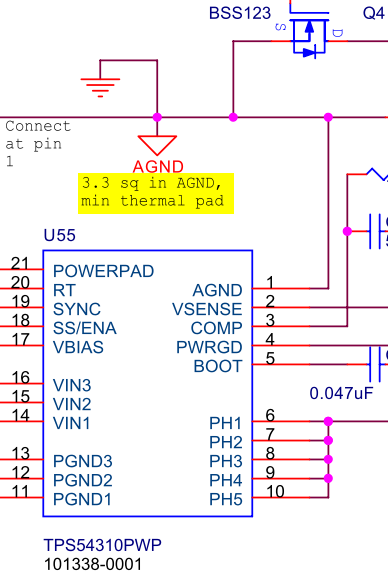

What does the highlighted texts in EVM6437 schematics mean? Is “sq” an area unit (square xx, etc.)? What does the “thermal pad” refer to? Do I have to buy any additional thermal pad, or TVP54310 already embeds it?

Thanks,

Zheng