Other Parts Discussed in Thread: BQSTUDIO, GPCRB, GPCRA0

TI support,

RSOC has not reflected the battery capacity at real time.

I have finished until learning cycle(LStatus 0x0e). I believe it's ready to use.

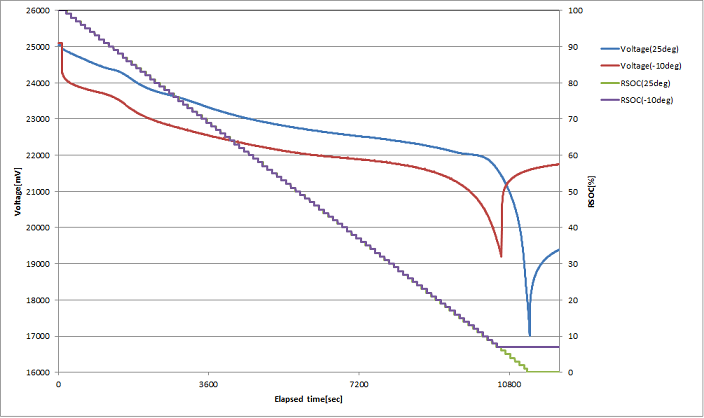

But prior to mass production, I did the test of discharge characteristic using logging by bqStudio at different temperature as shown below:

(I need wide range of temperature in my application.)

1. Charge the Li-po battery(6S 1P) to full at 25degC of temperature.

2. Discharge to empty(rate 0.3C) at 25degC. I got the graph of discharge on Voltage and RSOC at 25degC.

3. Charge to full at 25degC.

4. Left the battery at -10degC well-relaxed over 4 hours.

5. Discharge to empty(rate 0.3C) at -10degC. I took the graph of discharge on Voltage and RSOC at -10degC.

Results are:

25degC: RSOC=2% at 3V/cell

-10degC: RSOC=7% at 3V/cell

Continuing discharge at -10degC almost reached at less than 2.5V/cell(dsg stopped), RSOC still kept 7%, though.

Why RSOC does not decrease by following the ambient temperature?

Please let me know any concerns or suggestions you may have.

Regards,

Kunny