Dear experts

We have some confuse of this device as below:

1. if the charger is still higher than the TAPER CURRENT, but the FC have been set to 1, does this normal?

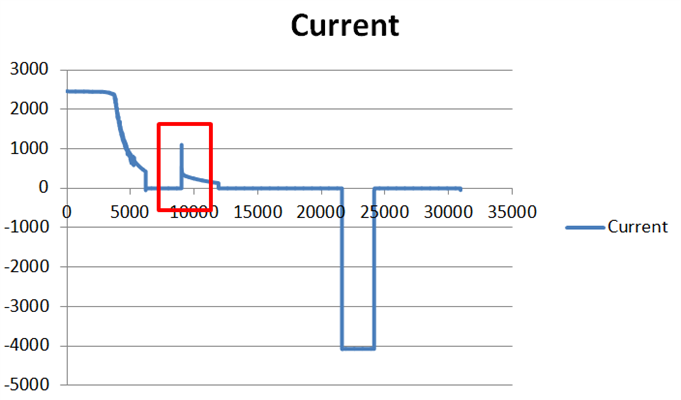

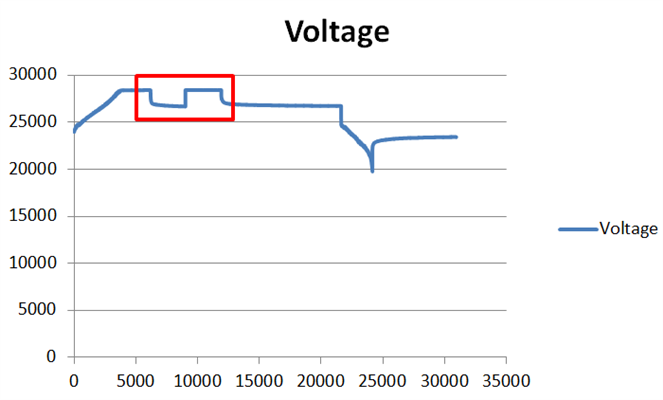

2. if the discharge current is high, so the voltage drop of the battery is high, this will make the SOC jump to 0, customer want to know if there have some work around in this condition?

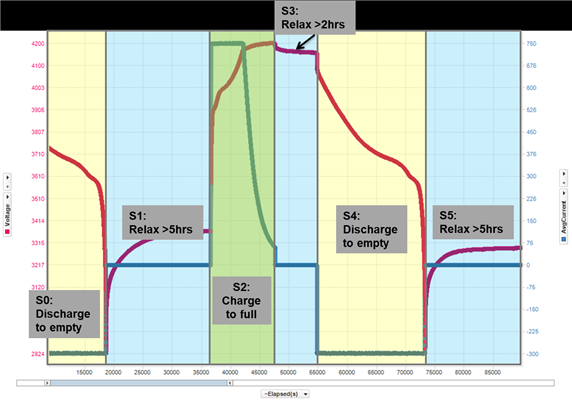

3. learn cycle, UPDATE STATUS start from 0x04, and after 5hours, it changed to 0X06, no 0x05 state, so this is a success learn cycle?

4. after learn cycle, the QMAX have a update, but the Ra table do not have change, so will this firmware working for the production?

5. after the learn cycle, the SOC jump from 0 to 23%, so this is because of the reset order? and judge the SOC just form the cell voltage.

6. for mass production, after load the firmware, should customer doing some order sequence? like reset, IT_ENABLE?

Thanks

B.R.

Jun Shen