Hi,

my customer experience problems with TPS61070 during manufacturing. Please advise what can be done to isolated / fix the problem:

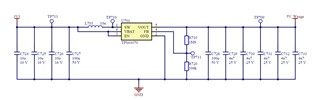

TPS61070DDCR is used in one of our PCBs as booster to generate from an input voltage of 3,3 V an output voltage of 5,0 V.

Testing the PCB (after the PCB assembly) with an In-Circuit-Test (ICT) the output voltage is at 5 V -> so the PCB and the part is working fine!

But after the assembly process of the device (in which we mount this PCB) when we perform a Factory Acceptance Test (FAT), we have had a few cases in which this part is not functioning correctly.

Then we (have to) disassemble the PCB and found one of the two following problems:

1. the part is heating up with an output voltage of around 3,1 V (instead 5 V).

2. the part is "dead" with an output voltage of 0 V.

Since this problem occurs frequently

we want to discuss, whether this is a known topic and there are already some possible solutions. Or whether we may have a circuit error on the board (design fault from our side).

Or whether we have a faulty charge which we have to claim then.

Thanks

Josef