Other Parts Discussed in Thread: BQSTUDIO, BQ40Z50, BQ34Z100

Hello Team,

We have used the BQ27Z561 in our project.

Here are the brief specs of the battery.

- Battery Voltage - 3.7V

- Battery Capacity - 30AH

- Battery Chem - Li-ION

- Battery Config - 1S10P

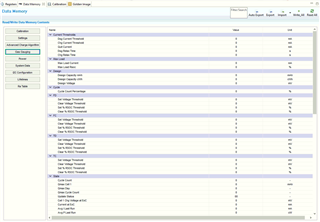

We have the Chem-ID for the battery.

We have started the Learning Cycle for the same.

Currently, I have few queries the related to learning cycle.

- What is the critical parameter which needs to be taken care of during the learning cycle?

- What happens if charging-discharging relax time will be stretched?

- In the learning cycle Data parameter for the FC bit is 4150 V set, but still, FC is not set after the charging complete. I found that the battery voltage is 4185 at that time.

- Do we have IC limitations to read the battery capacity of 30AH?

Here I have attached the gg, CSV, log file, and log error files for your reference.

Let us know the next action items to achieve the successfully golden file generation as we are chasing this activity from 1 year without any fruitful result.