Hi,

Problem phenomenon: Long-time running, the detection rate is found to decrease.

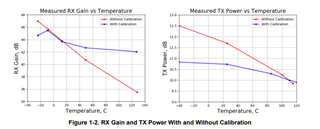

It is found to have a certain relationship with temperature. In the Application Report Self-Calibration in Ti's mmWave Radar Devices document Figure1-2, the runtime calibration function is described. The chip will self-adjust the TX\RX Gain value as the temperature changes. If we put this The gain is fixed to compensate a relatively high value. What impact will this have on subsequent mass production?