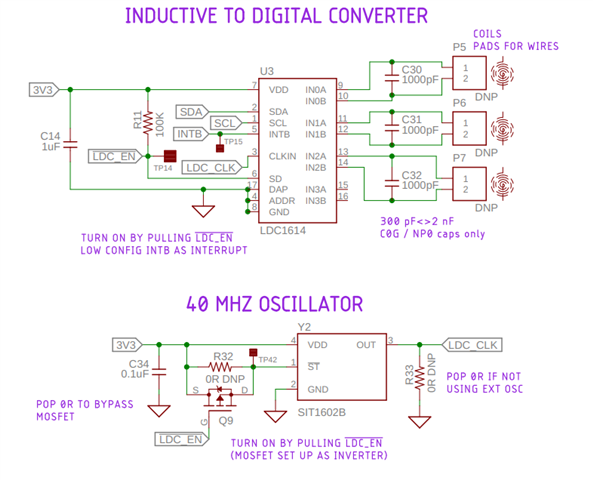

Setup:

LDC1614

4 layer, 10mm coils

Target is a stainless steel braided wire

Target distance is less than 1x coil diameter

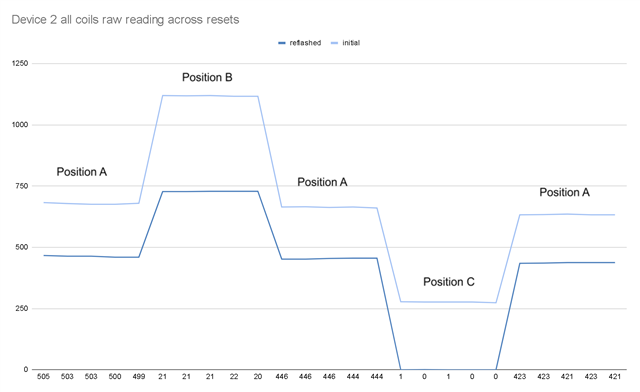

As the title suggests, I'm experiencing a drift over time in the raw values collected by my LDC1614 sensor. In the test, I held the target at position A, then moved to position B, back to position A, position C, position A. These are fixed positions for the purpose of this test. The test duration was about two minutes from the first reading to the last, and then the firmware was flashed, and the test was repeated. The vertical axis is the raw sensor value, subtracting the minimum from the range.

As the graph shows, there's a relatively significant change in the raw values read from the same position over a two minute period. There's also a significant change in raw values read between firmware flashes.

Is this normal activity? It's making it challenging to measure real-world distance to target, as our calibration values seem to lose meaning over time and between flashes/restarts. Could it be an issue with our reference oscillator?