Dear TI,

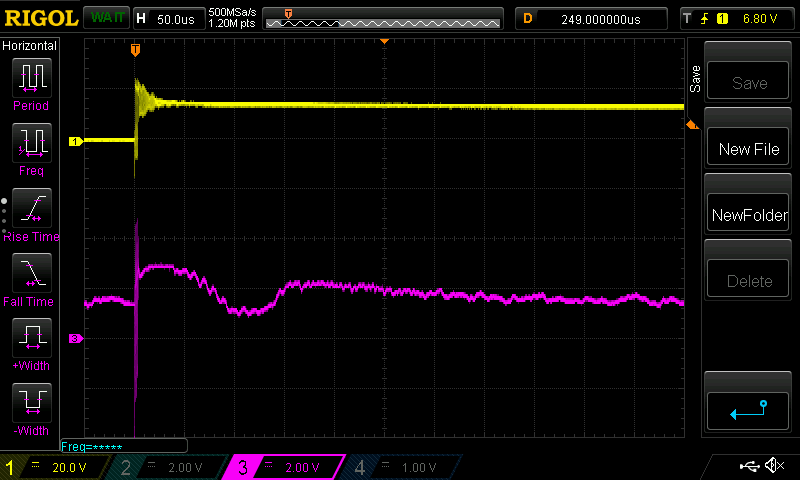

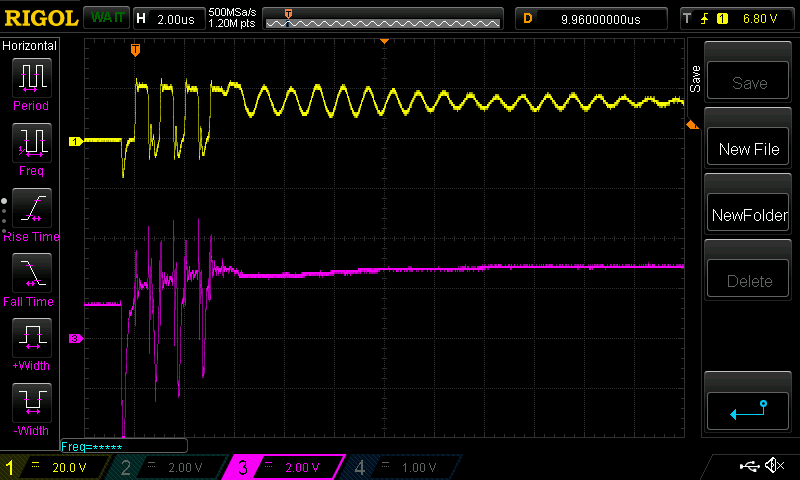

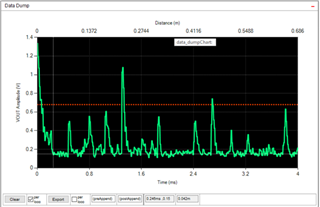

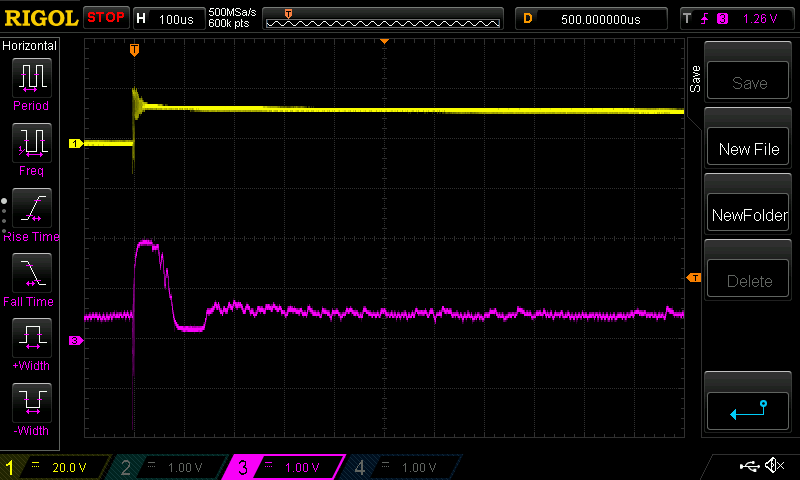

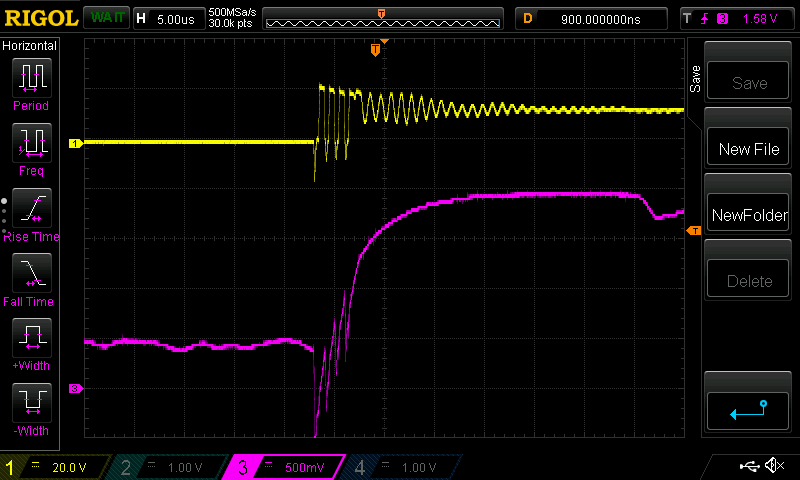

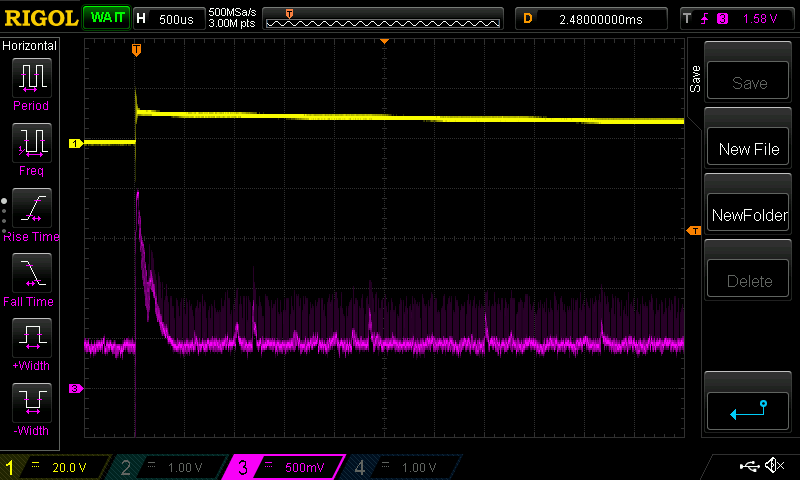

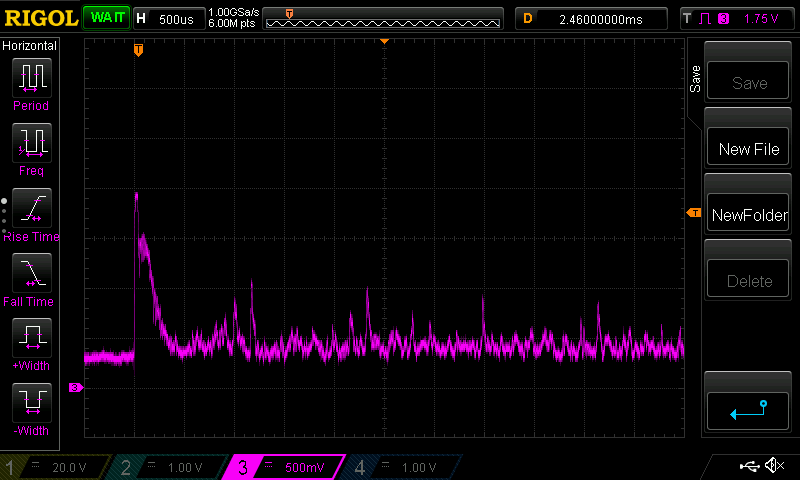

I've got a TUSS4470 on our custom board and connected to a PZT and we're trying to measure fluid level. The container this is attached to currently is metallic. I was wondering if you could take a look at my waveform to see if you can think of an approach to clean up or get a cleaner signal out. I can see 2 bumps which could be used to calculate the fluid level in this case but I'd like to see nice spike echo responses.

Here is my configuration setup:

Add Value

0x10 0x5F

0x11 0x00

0x12 0x1C

0x13 0x02

0x14 0x00

0x16 0x5F

0x17 0x13

0x18 0x54

0x1A 0x04

0x1B 0x02