Hello everyone,

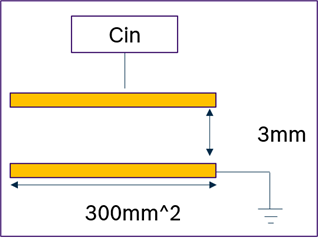

I want to detect the distance with a parallel plate capacitor. Is it possible to measure a distance of 3mm with an electrode area of 300mm^2 with the FDC1004EVM?

Is it possible to estimate the amount of disturbances such as noise etc. at this distance?

Or how accurately can the distance be measured at this distance if it has been calibrated for the distance?

Regards,

Maxi