Hi team

Customer would like to evaluate the device and they did not use it so have some questions to ask:

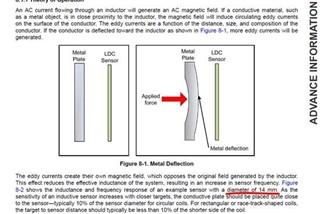

1. Must the metal sheet have to be deformed to be sensed? Is it possible to just move up and down to identify the displacement signal without letting the metal deform?

2. Whether the displacement recognition can reach the accuracy of 0.1mm

3. Does the metal piece need/must to be grounded?

4. Is there a mature application of the project, especially the automotive project?

5. What else smaller value could be used for the diameter since we think the 14mm recommendation is a little bit large;

Thank you in advance for your reply!