Other Parts Discussed in Thread: AWR2243

Hello,

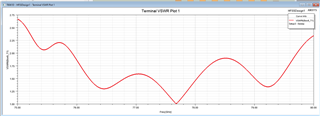

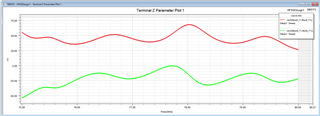

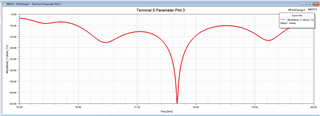

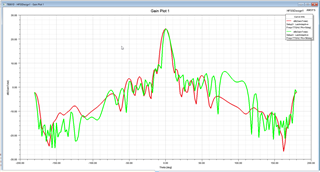

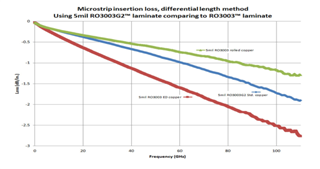

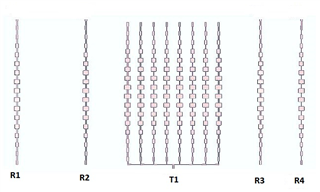

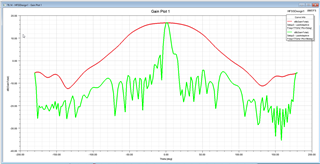

I am designing a high-gain antenna to replace the original one on the AWR1843Boost. Tx gain will be around 24dB and Rx gain around 17dB; thus it will have a very narrow beam to be utilized as stationary radar. SLL is around -20dB. Employing Ro3003G2. The simulations on the HFSS confirmed and satisfied our expectations. What could be your suggestions/warnings concerning the original pcb design and components.

Thank you.

Kind regards