Fluid sensing is useful in many different medical applications, such as infusion pumps and CPAP machines, where monitoring a dispensing fluid or liquid level is crucial to not only the system’s operation but also to a patient’s health. There are various position sensing technologies available like Hall-effect magnetic sensors and specialty sensors for fluid sensing, and selection of the right sensing technology depends on the specific use case and what degree of accuracy is needed when determining the volume of the liquid. There are numerous applications outside the medical field that need to detect the volume of fluid in a system as well, but this article will focus on medical applications in particular.

For applications where you only need to detect if the liquid level is high or low (to indicate if a container is full or empty, for instance), a Hall-effect switch with a floating magnet is a cost-effective and simple solution. When the magnet is at a distance outside of the Hall-effect switch’s predefined release threshold (BRP), the sensor will not detect the presence of the magnetic field, indicating that it is in the “off” state. The sensor will switch states to “on” when the magnet is brought closer to the sensor so that it crosses the sensor’s magnetic operating threshold (BOP). Other floating magnet configurations are also possible, such as attaching the magnet to a hinge that is connected to the container wall. Implementation of such a system is a relatively simple mechanical design process, and benefits from a contactless measurement solution that works with high reliability for any type of fluid or container.

The change of state of the Hall-effect switch could send a signal to your system to stop operation until the user refills the liquid or corrective action is taken. This implementation would be useful in applications with a liquid reservoir, such as a CPAP machine, to determine if there is enough water in the tank to create humidity. This solution does not only apply to medical applications and can be applied to any system that cannot operate properly if there is not enough liquid present. TI has a portfolio of Hall-effect switches that are offered in various options such as low/high supply voltage, different packages (SOT-23, X2SON, etc.) and unipolar/omnipolar to fit your system’s requirements. For an introduction to Hall-effect sensors, watch our TI Precision Labs series.

Some applications need to measure the throughput of a liquid through a channel such as a tube. Hall-effect latches are typically paired with ring magnets and can be used to measure the speed and direction of a motor in a liquid pump or flow meter. The alternating north and south poles on the ring magnet toggle the output of the Hall-effect latch which can be used to calculate the speed and direction of the flow meter or pump and from there the amount of liquid flowing can be found. This method of liquid measurement is useful for medical equipment such as dialysis machines where larger amounts of liquid need to be measured through a specific channel such as a tube. To learn more about rotary encoding check out our article Incremental Rotary Encoders.

For applications where higher accuracy is needed or where the liquid needs to remain sterile, a one-dimensional linear Hall-effect sensor can be beneficial. An example of this type of application would be a medical device such as an insulin pump where there is a mechanism similar to a syringe of liquid with a plunger that dispenses the liquid within the equipment. A magnet could be placed on the back of the plunger and as it approaches the linear Hall-effect sensor that is attached to the opposite end of the syringe, you can calculate how much liquid has been dispensed. This solution is contactless, meaning the magnet and sensor would not need to have contact with the liquid in order to determine the liquid level. The DRV5056 is offered in multiple versions, making this device ideal for head-on displacement applications. The different sensitivity variants enable support for various distance and magnet combinations in linear position applications.

A linear 3D Hall-effect sensor could also be used in applications where a higher degree of accuracy or different positioning of the sensor is needed. By placing the linear 3D sensor on the side of the syringe mechanism as shown above, the magnet will slide by the sensor and give an accurate output by using measurements from the X, Y and Z axes to determine the exact location of the plunger. A multi axis linear sensor, such as the TMAG5170, is beneficial in situations where head on displacement is not possible and more flexibility is required in the placement of the sensor or where the one-dimensional option does not offer enough precision.

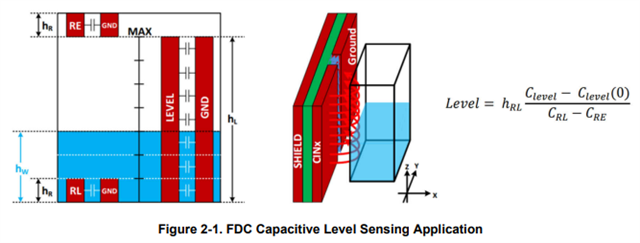

The last solution we will discuss in this article is capacitive liquid level sensing using the FDC1004. Capacitive level sensing is also contactless and can be used to accurately measure liquid height with a resolution as high as <1 mm. This device features active shielding to decrease interference from the outer environment and a flexible system design where the target can be any metal or conductor which is useful for low cost system design. In the diagram below, the sensors in the diagram on the left can be implemented with a flex PCB to fit round or cylindrical container shapes and allow sensor placement on various surface shapes.

The below technical articles are a great place to learn about the FDC1004 and how to implement it in liquid level sensing of fluids that are not conductive.

- What are you sensing? A novel approach for capacitive-based liquid-level sensing

- Capacitive-Based Liquid Level Sensing Sensor Reference Design

- FDC1004: Basics of Capacitive Sensing and Applications

- Capacitive Sensing: Direct vs Remote Liquid-Level Sensing Performance Analysis

There are many different ways to implement for liquid level sensing in medical applications in order to assist in monitoring a patient’s health as well as the system’s operation. Various position sensing technologies are available to use in fluid sensing applications, and selection of the right sensing technology depends on the specific use case and the level of precision needed when determining the volume of the liquid. TI has a wide variety of specialty sensors and Hall-effect magnetic sensors to fit your system’s requirements.