Hi,

I am using the demo from sdk_03_05_00_04 to generate the calibration coefficients with the following CLI command :

measureRangeBiasAndRxChanPhase

I also use the special profile_calibration.cfg file for that.

I am using a small corner reflector as a target at ~2m.

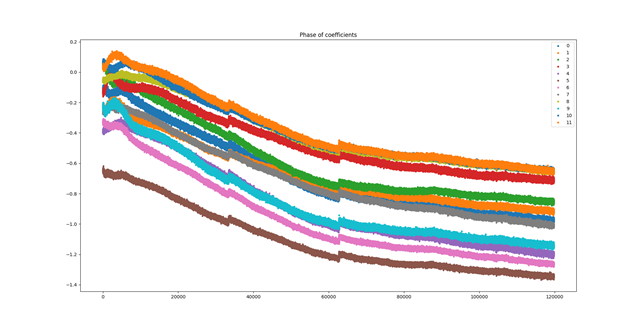

When I plot the evolution of the coefficients phase at room temperature (~10°C) during ~12 hours, I obtain a slow drift of absolute phases :

The relative phases are relatively constant.

When I do the same with a 60°->20°C temperature sweep (nonlinear sweep : only passive cooling), there are transitions where the relative phases change a lot (let's say the brown curve is ahead of the blue one and after the transition it is the opposite) :

I understand the radar performs continuously self-calibration as described in SPRACF4B, which would explain the transitions.

You can see that the phase correction coefficients will depend a lot on the temperature selected.

Are the coefficients valid only for the same temperature with the following CLI command compRangeBiasAndRxChanPhase ?

Or do we need to perform this operation only at room temperature, and the chip will compensate at different temperatures ?

Best regards,

Massimo