Other Parts Discussed in Thread: TDC1000

Team,

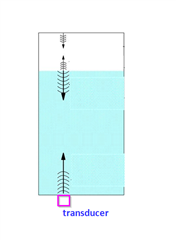

Is the below use case possible with PGA460?

The idea is to use the PGA460 BoostXL to test it and use a 300kHz sensor (from Multicomp) and a corresponding transformer on the board.

Testing with this transducer over the works and it can detect an object.

But it does not seem to work well in water, as propagation is much lower.

Can the principle work at all in water?

What parameters/settings would be best for this use case?

Will the GUI SW enable to test this?

I assume that there would be some side effect to consider (for example when the tank is almost empty).

Thanks in advance,

A.