Other Parts Discussed in Thread: OPT3101

Hi,

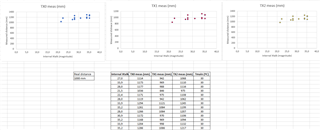

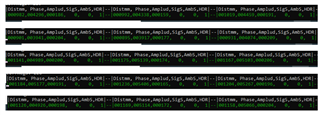

I am using a custom board which contains an OPT3101 with the three transmissions channels activated. After performing the calibration process using the SDK, the test step is run in order to measure different distances. Keeping the sensor at the same distance and the same environmental conditions, the test step is executed by turning the board on and off several times and the measurements obtained are different every time. I would like to know why this behaviour is observed and if there is any way to avoid it.

I attach below some captures of different measurements obtained at the same distance (1000 mm).

Thanks,

Olga