Hello there,

I would like to share an idea how to realize an inductive push button sensing solution above a small OLED display.

In a prototype mockup, it worked well for me with an LDC1614 device, but since then I have not brought it to production status:

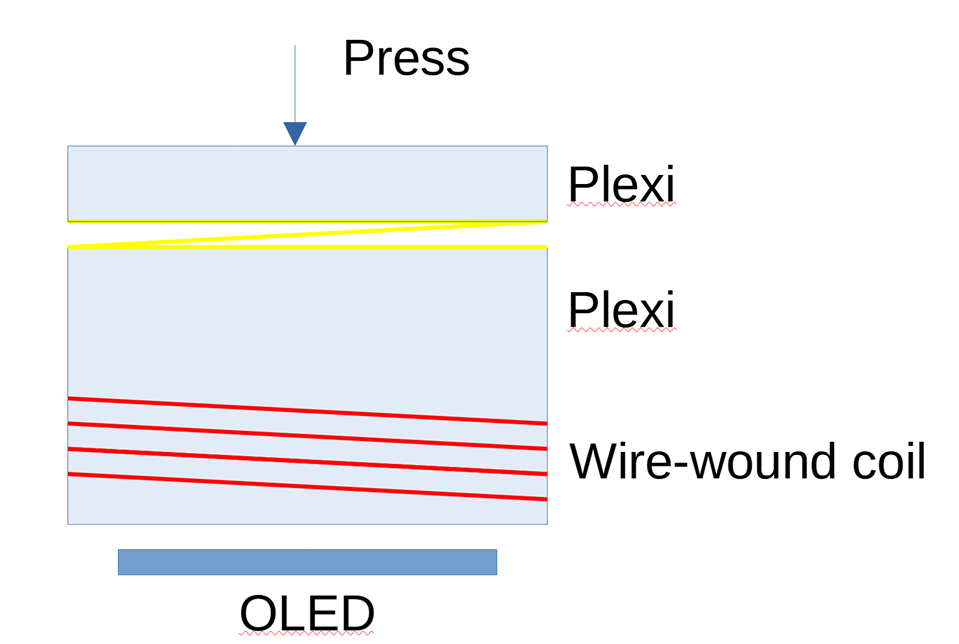

The sensing coil was wire-wound around a plexiglass disk, a PCB in form of ring shape might work as well but have not tested it.

The key-element of this construction is the spring between the two plexiglass bodies. Once compressed as far as possible, it will

act as a short-circuit winding, causing cause a huge inductance change in the sensing coil below.

I found this works well and reliable, even with a button-to-sensing coil distance of more than twice the coil diameter.

Hope this could be a useful application for some readers.

Regards,

Jo