We are using a LDC1612. We have some problems about this chip.

The inductance we used changes between 1 mH - 1.6 mH, Our parallel capacitance is Cp = 10 nF.

We configure the registers as follows, respectively:

void LDC1612_Init(void) {

LDC1612_Write(0x1C, 0x0000); // reset all registers

LDC1612_Write(0x1A, 0x1481); // config (Internal clock enable, INTB disable)

LDC1612_Write(0x1B, 0x0209); // mux_config (deglitch filter Bandwidth = 1.1 MHz)

LDC1612_Write(0x08, 0xFFFF); // max conversion time

LDC1612_Write(0x0C, 0x0000); // zero offset

LDC1612_Write(0x10, 0x07D0); // settling time = 0.8 ms

LDC1612_Write(0x14, 0x1001); // clock dividers: 1) fin_div = 1, 2) fref_div = 1.

LDC1612_Write(0x1E, 0xF000); // idrive (we selected this value by controlling it from the osciloscope screen to make sure 1.2 v < Vosc < 1.8 V)

}

1) Our oscillation signal on LC Tank is stopping after start-up. I mean it does not continue oscillating or sometimes, it oscillates for a period of time then it stops. What do you think is the problem?

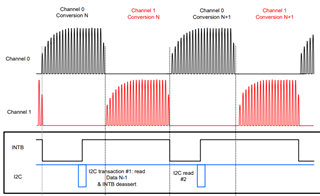

2) We designed a coil via webench tool. Lcoil = 8.5 uH, Ccoil = 100 pF. We obtained satisfying results. Then we switched the another setup and used the values we stated above (L = 1 mH - 1.6 mH, C = 10 nF). While we are changing the inductance value manually, we expect to see a smooth changing curve related to the inductance change. But, we see a discrete like curve. It feels like some data are missing.

What are your suggestions about these problems?

Thanks in advance.