Other Parts Discussed in Thread: TMAG5111, TMAG5170, , TI-SCB

Hi, We are looking for a replacement for another Hall Effect sensor we have.

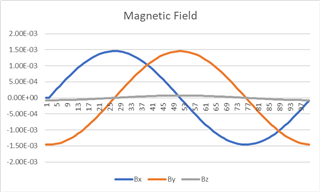

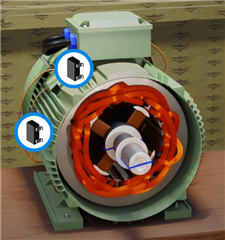

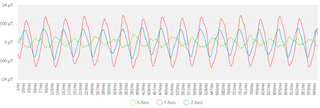

The sensor is on top of a electric motor and we are recording X, Y and Z magnetic fields to calculate RPM and direction. The accuracy is not very important but the sensor must have a good sensitivity.

The current sensor is capable of reading changes in magnetic fields 30cm away from the magnet, while the TMAG5273 A2 only change values starting ~10cm away from the sensor.

Am I using the wrong sensor for this application? Is there a way to increase sensitivity and gain?