Other Parts Discussed in Thread: MSP430F5529, MSP430G2553, TMP61

Hi Expert,

Our customer would like to achieve +/- 1C temp error with TMP6131QDYARQ1. I see the requirement in this e2e thread. But there are several items they cannot meet

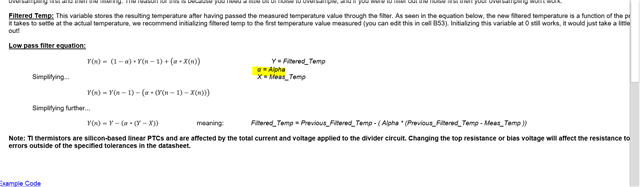

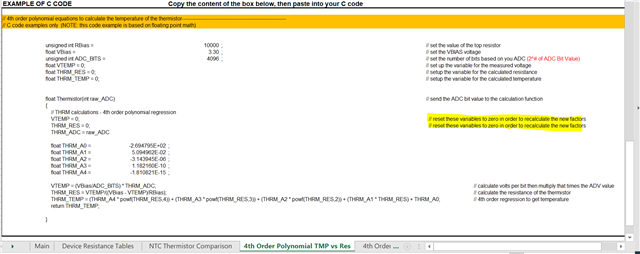

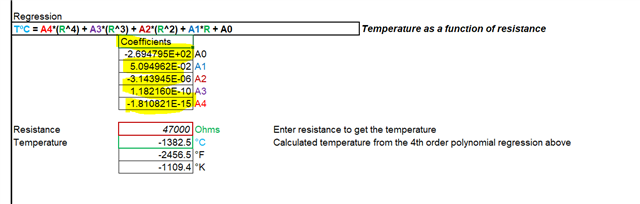

First of all, the ADC the use is 12bit. And due to MCU resource limit, they cannot implement 4th-order polynomial. They plan to use 2th-order instead. Under these conditions, can they achieve +/- 1C temp error result?

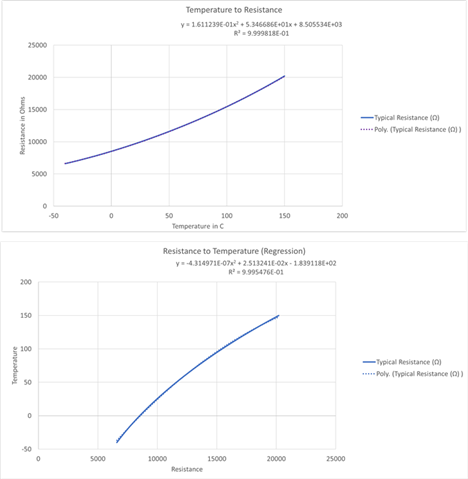

Another question, what's the procedure of applying 4th-order polynomial? What does it mean marked yellow?

And what about the coefficient? Does it apply to all TMP61-q1 ? Or is it just an example and the customer need to calculate themselves? Thanks.

BR,

Elec Cheng