Hello,

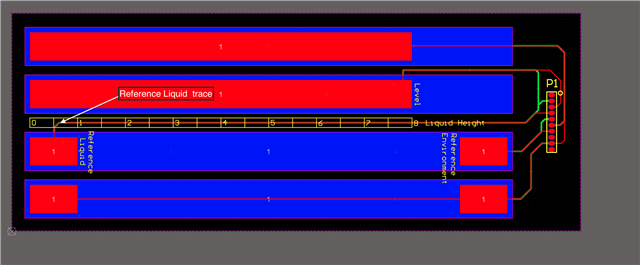

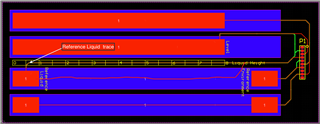

I am trying to develop a custom OoP liquid level sensor system using the FDC1004 based on the reference design. Because of system requirements, I have to have the Reference liquid sensor at the opposite end of the pcba from the FDC1004 chip. I am wondering if the liquid level is affecting the capacitance of the reference level since that trace runs the length of the circuit. I also run a trace on the other side of the PCB to help shield the signal line.

Any and all suggestions would be appreciated.