Other Parts Discussed in Thread: LDC1614

Hi!

We are already in serial production with sensors that utilizes LDC1314 on-board. Regarding the performance, there were no complaints so far. We already used several thousands of the chip and faced no issues. However, recently we faced issues with multiple failures during EOL testing regarding certain limit checks.

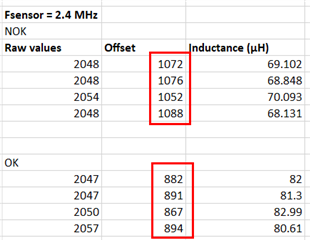

The inductance values of the coils measured by the LDC1314 was the issue. Hence, we segregated the OK and NOK sensors, measured the inductance of the coils using LCR meter, checked the BOM if there are any exchange of components etc.

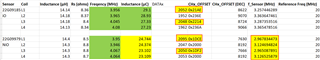

Sensor -> Sensor name

Coil -> Naming of the coil to be measured

Inductance (µH) -> Measured externally using LCR meter

Rs (ohms) -> serial resistance of the coil (measured using LCR meter)

Frequency (MHz) -> Frequency of the coil under oscillation state (measured using oscilloscope)

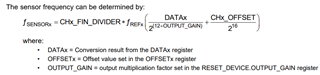

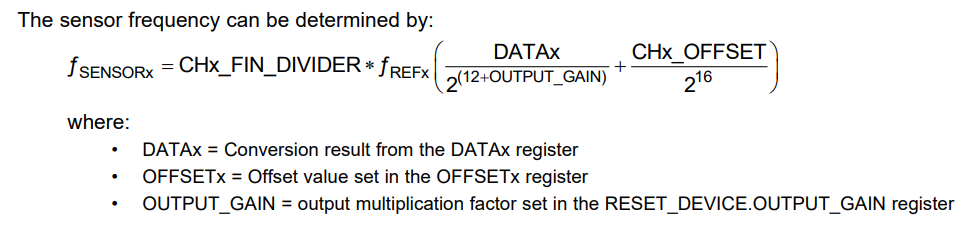

Inductance (µC) -> Inductance value measured by the microcontroller using the values obtained from LDC.

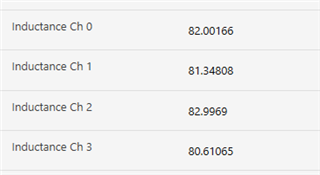

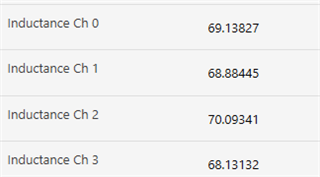

As seen from the figure above, the physical inductance, serial resistance and frequency of individual coils are pretty much comparable and within the limits. However, the inductance values calculated from the µC deviate by a considerable amount. Since the µC Firmware was the same across both the OK and NOK sensors, we checked the batch of LDC, and we found the following.

LDC1314 84U ATNT -> NOK sensors

LDC1314 13U ALEO -> OK sensors

It will be great if you can help me in finding out why such a deviation in measurement is happening, that corresponds directly to the production batch of the LDC1314. Please let me know if you require additional information.

Thanks!