Other Parts Discussed in Thread: TDC1000

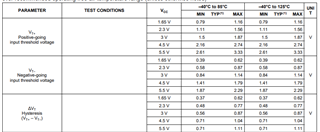

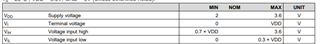

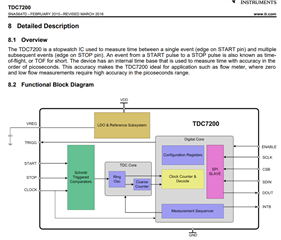

The TDC7200 datasheet includes a block diagram that indicates "Schmitt Triggered Comparators" on the START/STOP inputs. But the electrical specifications seem to contradict this.

Which is correct?

Based on other answers in these forums I believe the block diagram is incorrect, and there are no hysteretic comparators. But I would like confirmation.