LM35DT/NOPB/TI

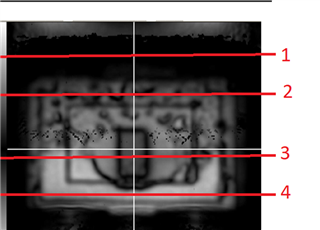

The delaminations are extended to the resin/paddle interface, they are in the bonding zone, which is not acceptable on this type of component.

the delaminations are too big between the resin/paddle interface

1) Die Attached Epoxy overflow is common for this product type, and

2) The C-SAM observation is normal and acceptable?