Other Parts Discussed in Thread: TIDA-00322, TUSS4470, , TDC7200

Hello everyone,

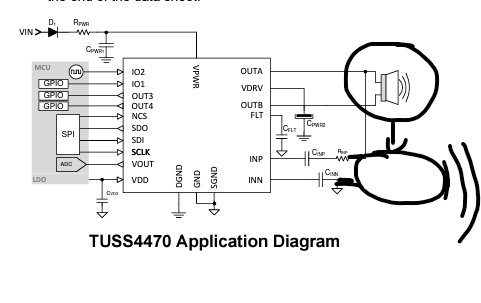

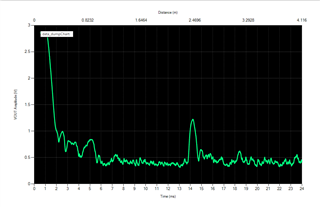

I am interested in building a fluid identification device that measures the time of flight (ToF) through a liquid and determines the liquid present based on its density. I have looked into the TDC1000 and specifically the TIDA-00322 reference design's test report to see if it's suitable for my application.

However, I am looking for a product that can measure the speed of sound more accurately and precisely, with an accuracy of around +/- 2 m/s at the speed of 1600 - 1000 m/s, through a fixed distance of no more than 10cm (from transducer to acoustic-reflective surface). Based on the test report of the TIDA-00322, it seems that it cannot meet my requirements.

I have a few questions:

1. Does Texas Instruments offer a more accurate and precise solution for my needs?

2. If I change the size of the transducer, will it affect the results provided by the TDC1000?

3. Is it possible to purchase the TIDA-00322 instead of building it from scratch?

Thank you in advance for any advice and guidance you can offer.

Best regards,