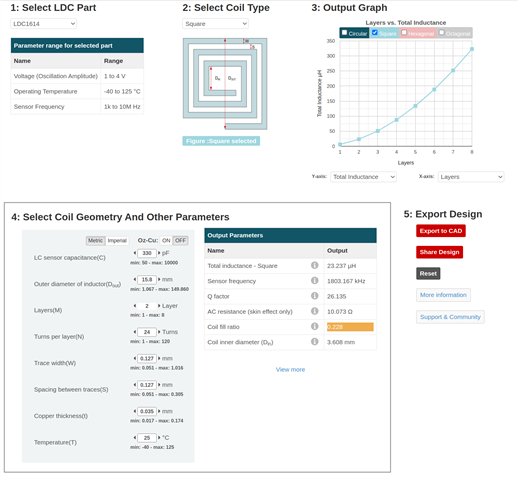

Hi, I’m experimenting with a LDC1614 on a custom board with a PCB coil. While it generally works fine, I get jumps in the output signal when moving towards and away from the target. To have precise movement I mounted the board to a 3D printer. The following diagram shows the output values when moving from 15 to 4 and back to 15 mm. This is very reproducible.I tried also horizontal movement over a slanted piece of metal to ensure that it is not a mechanical problem of the Z-axis.

I also moved it by hand, and while the output was quite shaky, the jumps were still visible. The board has a 40MHz crystal oscillator but I tried also with the internal clock with a similar result

(output values in a slightly different range and more noisy). The oscillation seems fine:The frequency is quite close to the results from the TI webench. I also measured the resonance frequency of the coil/cap which also matches that. I set the drive current by measuring the output voltage with the oscilloscope and

manually tuning the DRIVE_CURRENT parameter to be in the recommended range. I tried with channel 0 and 2 with the same results. I dumped the relevant registers for channel 2: 0x0a:0x26a0 0x0e:0x0000 0x12:0x0020 0x16:0x1002 0x18:0x0002 0x19:0x0000 0x1a:0x9601 0x1b:0x020c 0x20:0x9cc0 0x7e:0x5449 0x7f:0x3055 What do I miss?

br

Richard

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.