Hi TI,

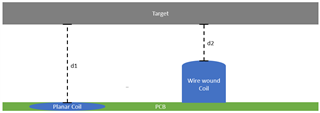

I'm working on a proximity sensor with the LDC0851 in a very small device and am looking to detect a metal object passing by at about 20mm from the sensor. We are in an early design stage and there are two design paths for the coil:

1. keep the coil within a 10x10mm surface envelope

2. enlarge the coil to a max 40x40mm surface - however, in this scenario there would be two permanent magnets overlapping with the coil surface

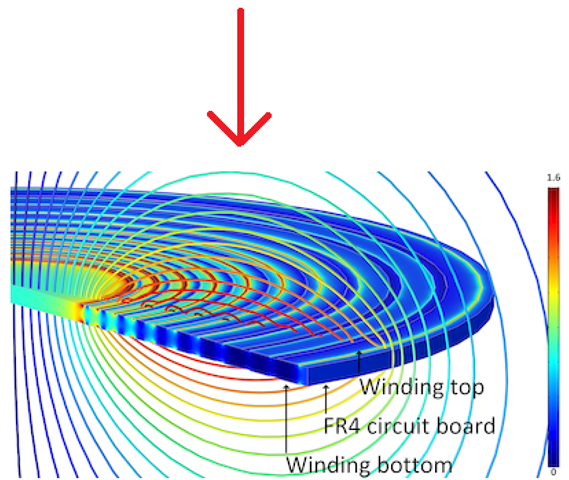

Since d_switch would be 3,75mm with a PCB coil of 10x10mm and ADJ of 1 (equation 1: par. 8.3.3 in the datasheet) that is not going to suffice. Therefore I am interested in knowing what the design steps would be for a wirewound coil; would that enable me to increase the available inductance within the limited envelope of path 1?

Alternatively, in path 2 the max sensing distance according to Eq. 1 would be 15mm. In that case, we can again consider a wirewound coil, but then I'd be interested in how the permanent magnets would affect the field. Could this be mitigated with ferrite shielding for example?

Thanks in advance!