Hi there,

We are looking for a method to sense distance between an actuator arm and a mating surface. I wanted to ask if you had a suggestion for sensor technology that could work for this application.

Some details:

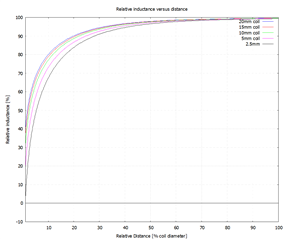

- The mating surface is plastic, but is mounted to a steel plate, so inductive sensing could be used to sense this steel plate, the plate is 23 mm from the sensor

- A magnet can be embedded in the plastic mating surface with a minimum distance of 17mm to the sensor

- Need a sensing accuracy of +- 1mm

- The mating surface is not even, so a capacitive sensor would not be able to locate the correct position

I looked at Hall effect and inductive and believe inductive would be better, as I am not sure if accuracy of 1mm is possible with hall in this application.

Let me know if you have a suggested sensor or need any more details.

Cameron