Hi,

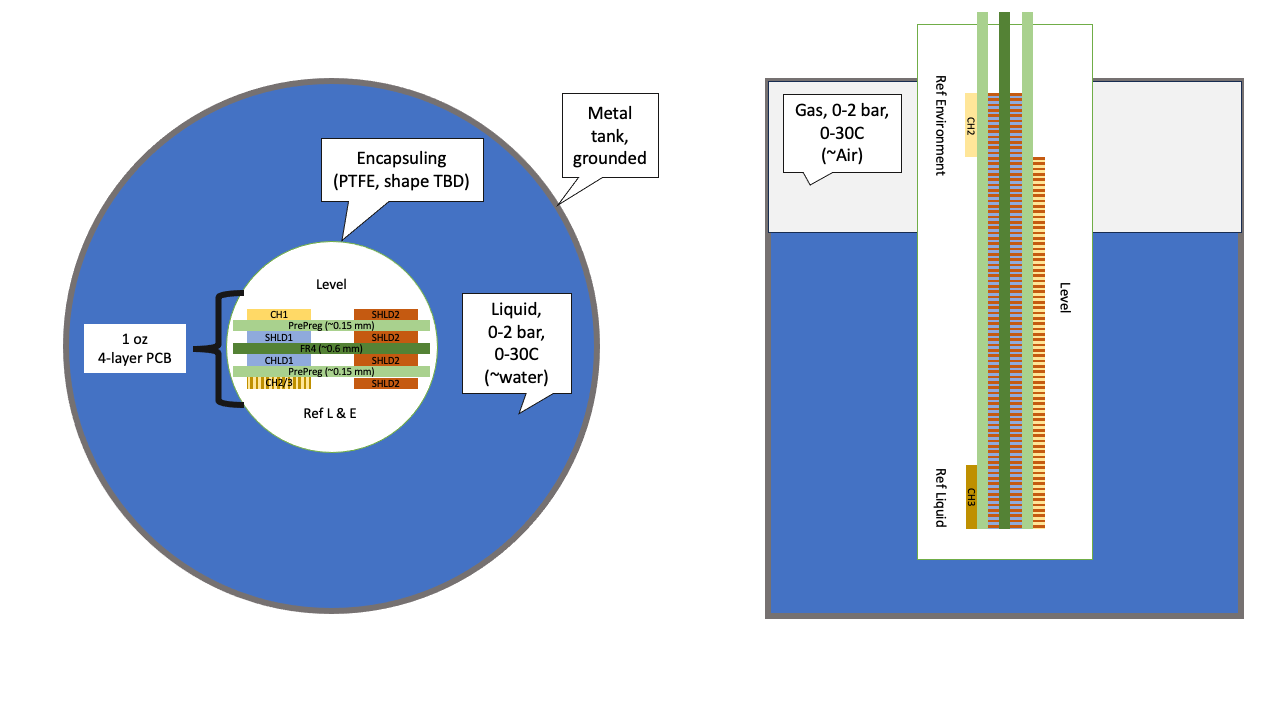

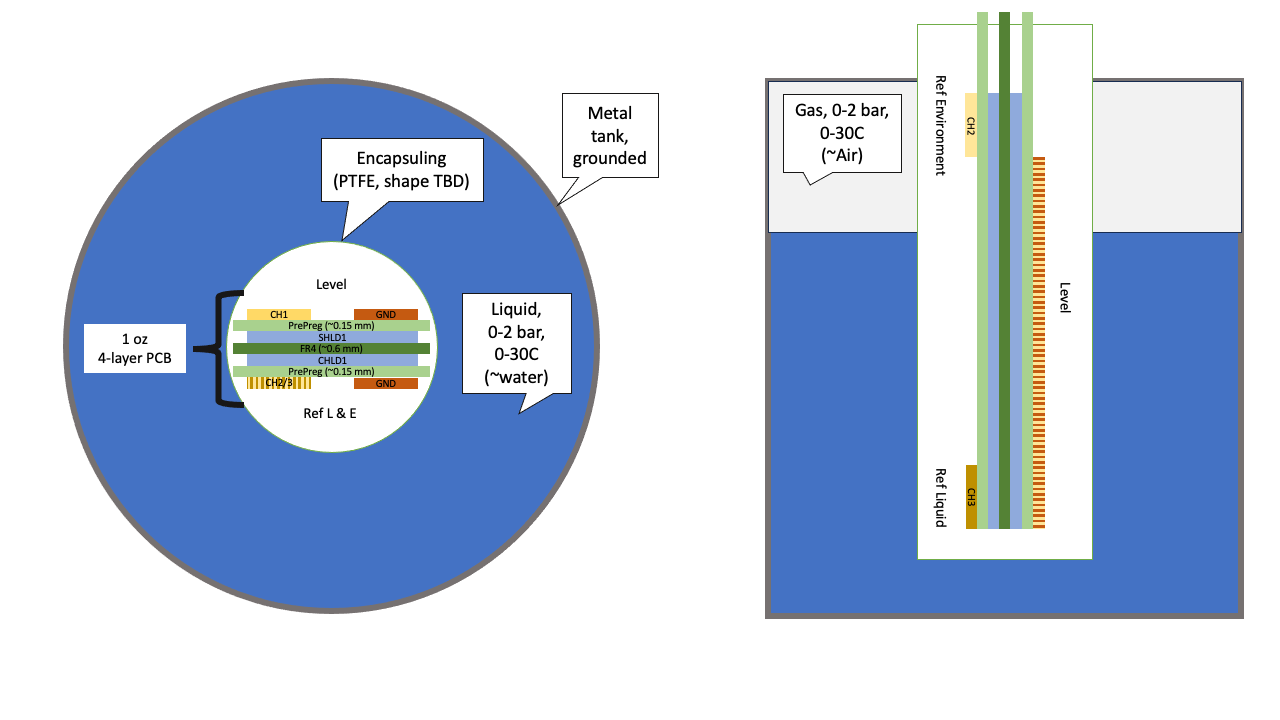

Working on a design for measuring liquid level in a grounded metal tank using the FDC1004. I would like to minimize the size of the sensor in the radial direction and would like to know if it is ok to have the level electrodes and references on opposite sides of the sensor. I've been experimenting with foil and the FDC1004EVM and it works great but before I send the design to a PCB fab house I would love to hear your thoughts!

I was thinking that it would be nice to have the sensor made out of a 4-layer PCB.

The tank is grounded, do I need to use the OoP design or is the conventional design ok in this case?

Do I need the RE reference? The temperature and pressure of the gas vary a lot.

Do you foresee any other problems with the proposed design(s) below?

See attached images!

OoP design on a 4-layer PCB

Conventional design on a 4-layer PCB

Any help is greatly appreciated.

Best regards, L