1 : Consistency problem. Currently we use FDC2212 two channels in single-ended mode, 10PCS board inside, the same conditions to collect the capacitance consistency is very poor. There will be a 2pf gap between different devices. But the amount of change in capacitance is relatively similar in detecting water.

I would like to know if you have done any testing on this consistency problem? Is this poor consistency problem reasonable?

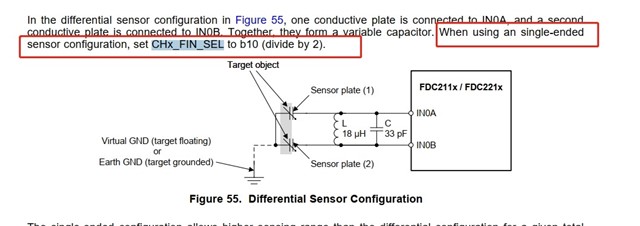

2: Single-ended mode and differential mode software register configuration issues. Before and you have communicated, single-ended and differential, only the hardware wiring way is different. Software does not need to be modified. However, I have seen the specification description. Single-ended mode is to configure the register. Please confirm if this has any effect. Is this configuration necessary?

3. Regarding the calculation of the measured capacitance value. Do you have a relevant calculation formula? Preferably, there is an actual code routine that can be provided for our reference.