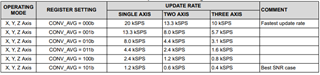

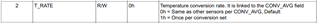

Now we have question for continuous mode. I see registers and if understand well 010b = 2h, in active measurement mode is always low power mode time delay. So this mode is for our purpose (motor commutation ) not good because we have 1ms regulation loop. Minimum time of low power mode between measurement is same 1ms. Do I understand it well?

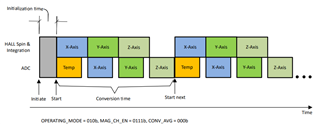

Then I have to use Trigger mode, start conversion on CS pulse. Then I can achieve without filtration 13.3 ksps for 2 channel (angle) sensing, Am I right?