Hi Team,

We use two LDC1614 for detecting 8 steel rode of 6mm each.

The antennas we're using have 22 turns and 4 layers, with an external diameter of 16mm and an internal diameter of 2mm. Our bulk capacitor is a 470pF in X7R. The operating frequency is approximately 1MHz, and we have an external oscillator running at 40MHz. We have approximately 1.7V at the antenna.

During testing, we observed that the frequency variation is initially satisfactory for detecting the rods, with around 40,000 counts. However, over several hours or days, we encounter a drift in the sensor readings that exceeds the threshold value.

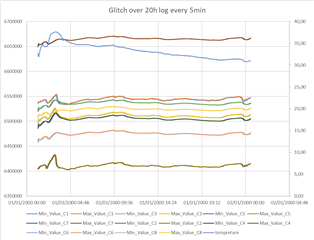

To illustrate, we created a chart depicting the values of one antenna over a week. We sampled the sensor every 100ms, and every 5 minutes, we recorded the maximum and minimum values. Despite having low noise, we are experiencing a significant drift.

The same mesurement are made during 20h over all 8 antennas while incorporating temperature data from one of the sensors.

We are seeking your insights on the potential causes of this drift. Could using a higher or lower frequency result in greater stability?

Thank you,

Regads,

Léon MARI