Hello,

I have some questions regarding the mecahnical drawing in the datasheet and the shown /specified position of the sensor within the housing.

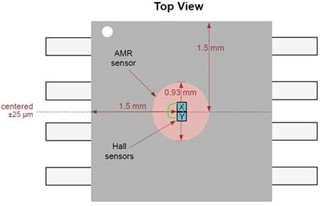

It is not clear whether the tolerance value “centered +-25µm” is the alignment of only the AMR sensor, only the Hall sensor, or both in regard to the package center. Which of these cases is correct?

What is the positional tolerance of the ARM sensor to the Hall sensor?

The alignment tolerance on the x-axis is not specified. Could you provide this value?

Further the horizontal arrow does not reach to the middle of the ARM / Hall sensor, but ends at the hall sensor (encircled in green). Without the knowledge of the width of the Hall sensor this value has no purpose. Is this intended? Shouldn't the arrow end in the middle of the sensors?

Are the ARM sensor and Hall sensor technically aligned to the housing or to the device pins?

Best regards