Dear Team & dear community,

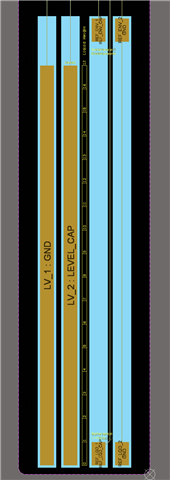

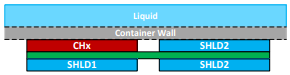

we are evaluating the FDC1004 for a liquid level sensing application for a medical device. The setup follows the reference design as proposed in this design guideline (https://www.ti.com/lit/ug/tidu736a/tidu736a.pdf?ts=1690711312623).

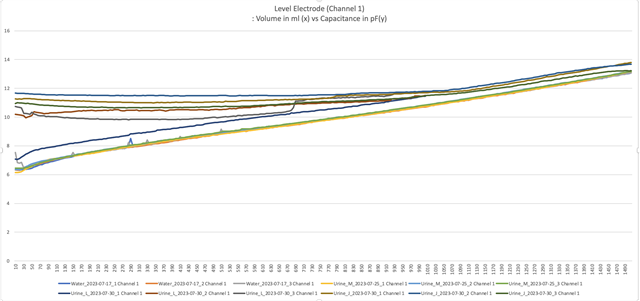

Mostly this works great, meaning we are seeing measurements of the level electrode with the empty container starting at around 6pf and proportionally rising until 12pf when the container is full. The measurements are accurate and repeatable.

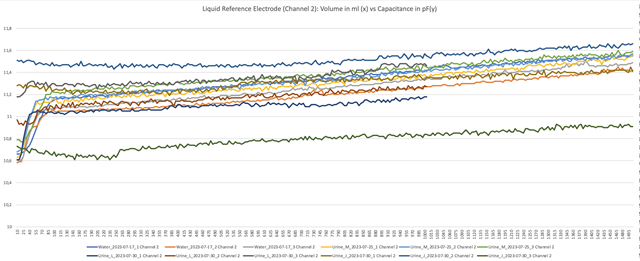

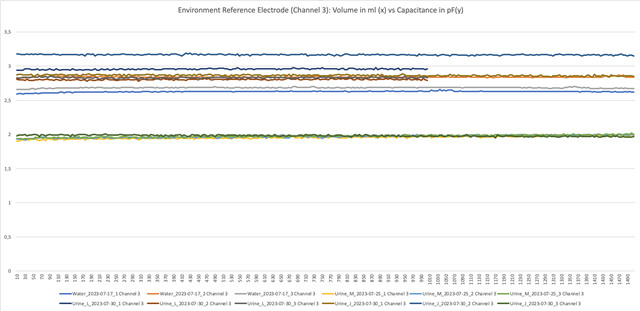

Sometimes however, without any apparent cause, the entire system characteristics spontaneously change: The level electrode with the container being empty now measures 10pf and rises to 12pf when the container is full. Liquid reference and environment reference electrode values change as well.

A restart of the system does not fix the problem. However, after waiting several hours the system will eventually revert back to its usual characteristic.

Despite of a lot effort (searching the forum, all app notes, improving the test stand etc.) we have been unable to find the cause or even to formulate assumptions of what my cause this problem.

Therefore I am kindly requesting your assistance since this problem could lead to an exclusion of the TI FDC1004 from our product development should we not be able to properly address this problem.

Thank you very much!

Best regards,

Mario