Hello,

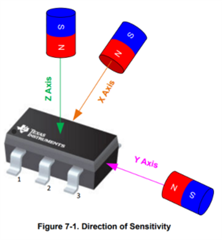

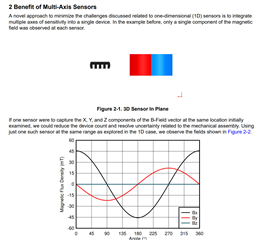

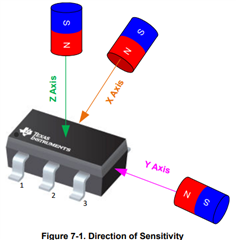

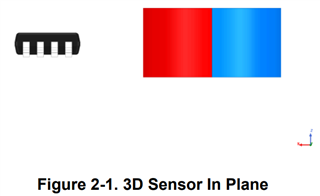

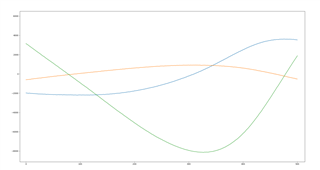

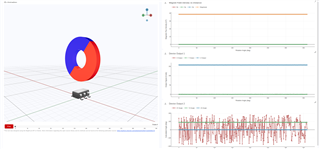

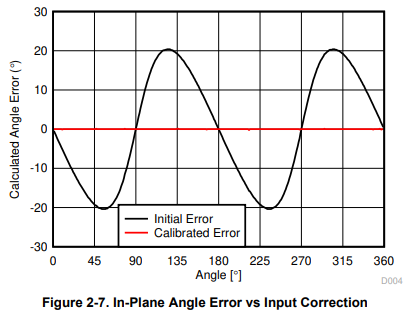

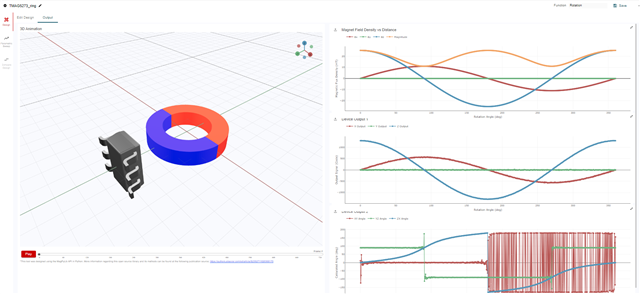

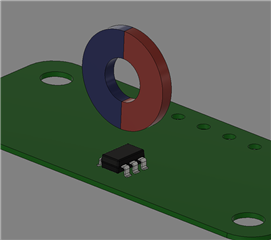

We are evaluating TMAG5273 for our application to detect the angle of a diametric ring magnet. For the given magnet/sensor orientation, would TMAG5273 be a capable sensor? Based on the Angle Measurement With Multi-Axis Linear Hall-Effect Sensors Application Note, my use-case seems similar to the In Plane scheme, with the sensor rotated 90 degrees.

- Would the internal angle measurement work best with the YZY mag channel configuration?

- The datasheet specifies that reads need to be synchronized with the conversion update time to avoid reading data while the register is being updated. We cannot use the interrupt pin in our application, but would prefer to use continuous conversion mode. Are the registers in an undefined state when being updated? or is the worst case scenario that the MSB register is not from the same conversion as the LSB register?

- What is the expected behavior of the sensor data registers if the magnetic field is stronger than the maximum sensitivity? Do they saturate or exhibit undefined behavior? During a quick test, I noticed the z-axis sensor data value jumping between ~20000 and ~100.