Other Parts Discussed in Thread: , LDCCOILEVM, LDC1612, LDC1101

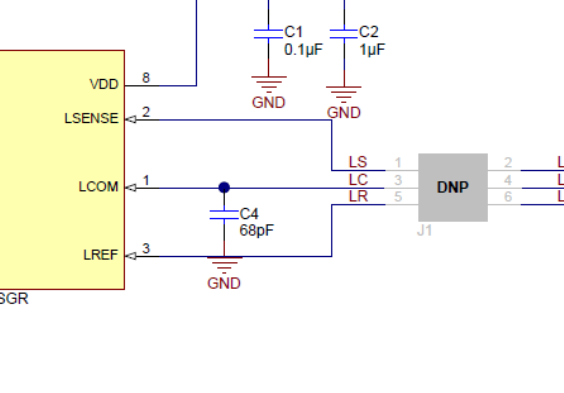

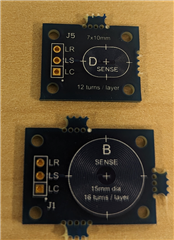

I have a project that uses a steel plate ~ 8" in diameter and is .125" thick. This plate sits orthogonal to the product and eventually falls ~ 90 degrees coming to rest ~20mm above the product. The goal is to detect when the plate has fallen and initiate a reset of the plate to the previous orthogonal position. I am looking for design guidance on the optimal coil for this sensing application and the optimal position of the sense and reference coils. I have approximately 1" of depth in the packaging and could increase that by .5 inches if needed. The top cover of the product is ~ 3" wide and 5" long and is rectangular. Conceivably a coil could be integrated into the cover and a reference coil into the base but that will also have a cost impact as well. Ideally having both coils on a PCB mounted as close to the target as possible would be ideal but may not be optimal for the sensing distance required. I was looking for someone that has experience with this product and can advise beyond the datasheet. Currently the product has been tested with externally actuated hall effect switches and normal microswitches but eliminating them is desirable if cost can be managed. Ideally the output of the LDC0851HDSGT would drive a mosfet gate, but power management could be done in other ways as well. If custom coils are recommended can you provide wire or trace dimensions and layout for a favorable result?

Edit: Additionally the material used for the enclosure during prototyping will be PETG and likely ABS or PC/ABS in production. It is also battery powered so consideration to optimized coil design for a battery power source would be helpful. Sample rate will be very low. Every 10 seconds the micro will wake the sensor look for a fallen plate and either reset a fallen plate, or go back to sleep.