Other Parts Discussed in Thread: FDC2214

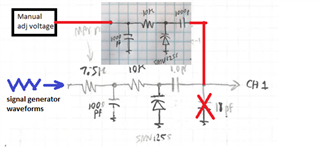

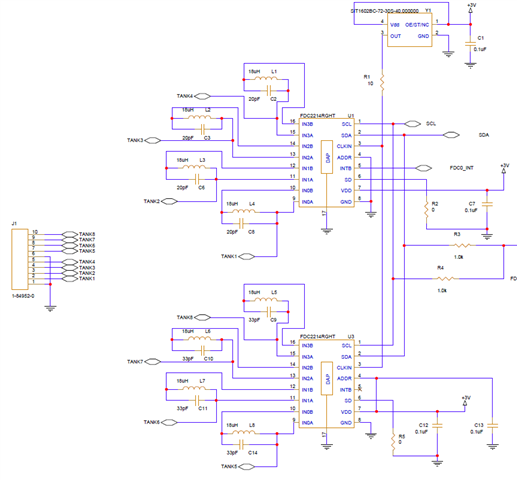

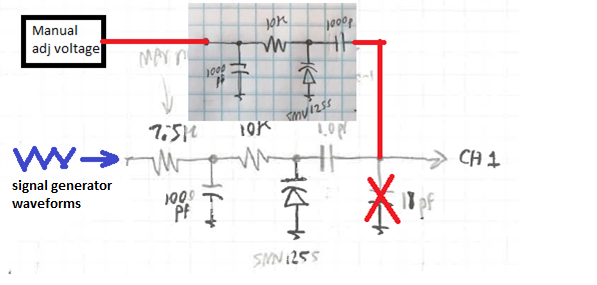

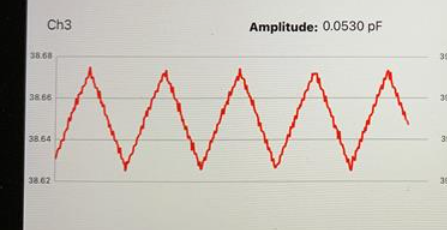

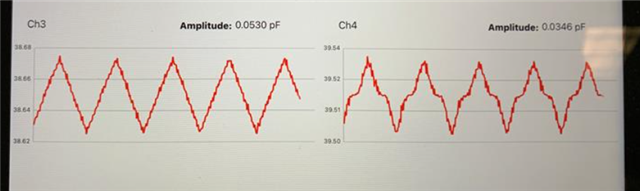

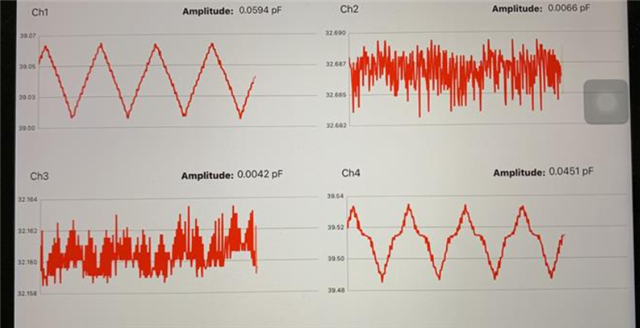

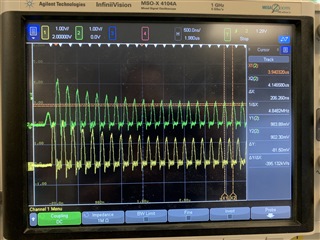

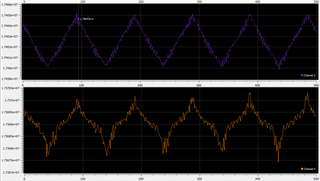

Hi, we have designed a capacitance sensor board using FDC2214 following the FDC2214EVM schematic. During testing we found there are dead zone of data read from FDC. The below graph shows what we observed.

The same triangle shaped signals are input to both ch2 & ch4, the graph is draw directly from data out from FDC's ch2 & ch4. We'd expect ch4 drawing shall be the same as ch2 in triangle shape. It seems there is a dead zone in ch4.

What could cause this phenomena? How do we remedy this, or any solutions to this?

Thanks!