Hi

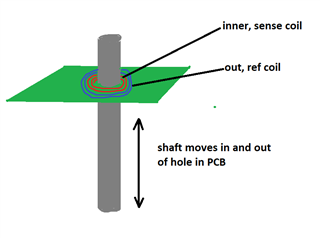

I was wondering if rather than the standard planar problem shown by many of the design references for the LDC0851, it would be possible to use this sensor in to detect the presence of a stainless steel shaft going through a hole in the PCB like the diagram below?

In theory the inner coil should have a higher flux density axially through the centre hole and therefore induce more eddy currents on the shaft than the out reference coil. Have you heard of any similar applications used elsewhere? Or is the "flat plate target" the best method still rather than centre hole and shaft idea? Thanks