Other Parts Discussed in Thread: TDC7201

Hello,

I would like to use the TDC7200 (or an alternative chip that might be more suitable for my use case) to continuously measure the time difference between an event and the clock. With this, I would like to capture the exact time of randomly occurring edges. Since the clock is known and I can roughly place the signal in it, I just want to use the good time resolution of the TDC7200 to determine where exactly the edge occurred within a clock cycle.

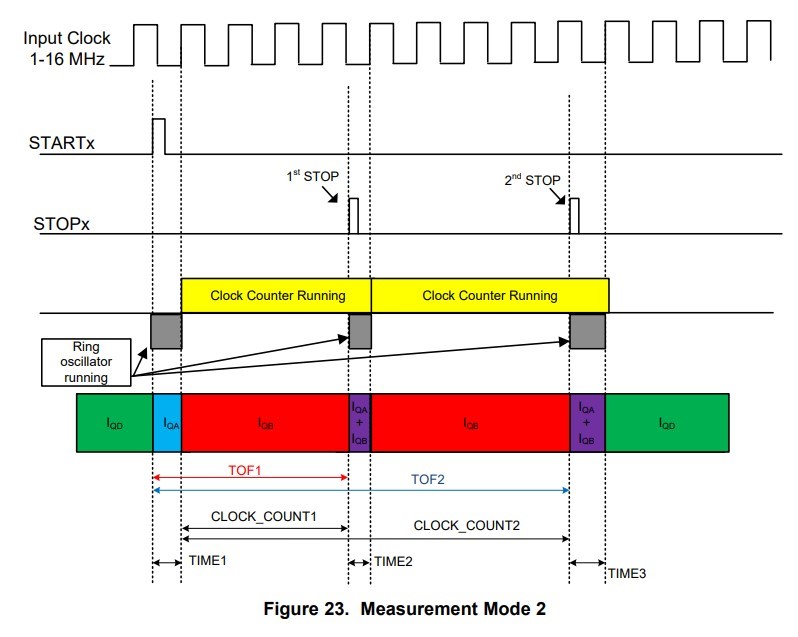

There is the Measurement Mode 2, where e.g. TIME1 is determined. This should be well suited to determine the difference between START and clock edge.

First question: Can a time shorter than 12 ns elapse between START and the clock edge?

Second question: I don't need a trigger from the microcontroller and even theoretically no stop signal. Is it possible to configure the chip in such a way that the TIME1 data can be acquired as quickly as possible after a START (and STOP) signal and that the chip is ready again very quickly for the next start signal?

Many thanks and best regards